Cathode Active Material

-

Lithium Iron Phosphate

-

Lithium Nickel Cobalt Manganese Oxide

-

Lithium Cobalt Oxide

-

Lithium-Rich Manganese-Based Material

-

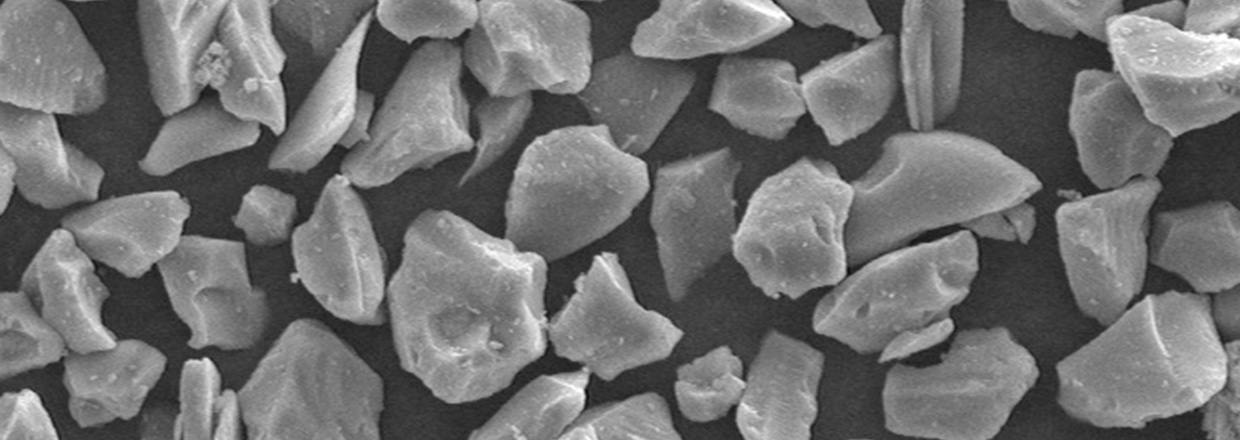

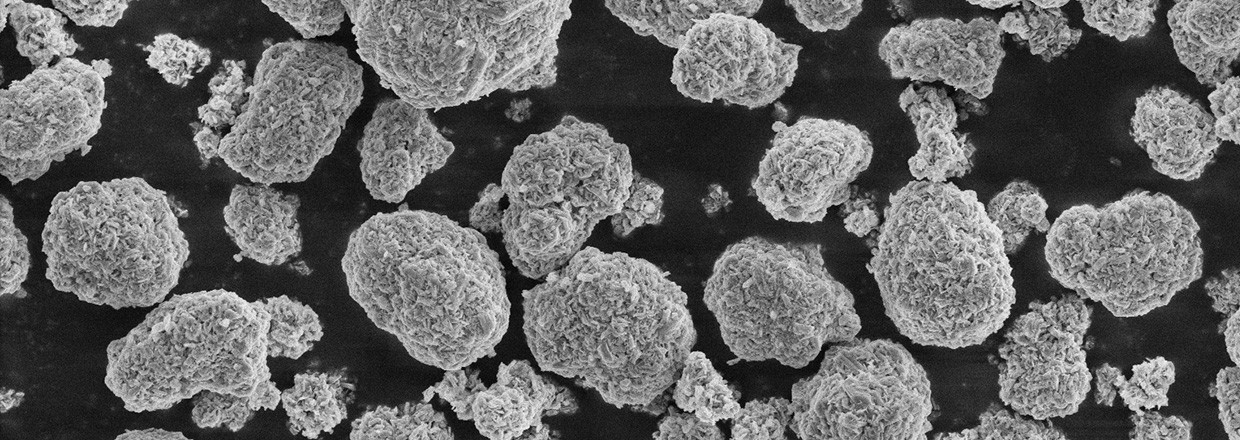

Recovered lithium iron phosphate

-

2nd-generation lithium iron phosphate

-

3rd-generation lithium iron phosphate

-

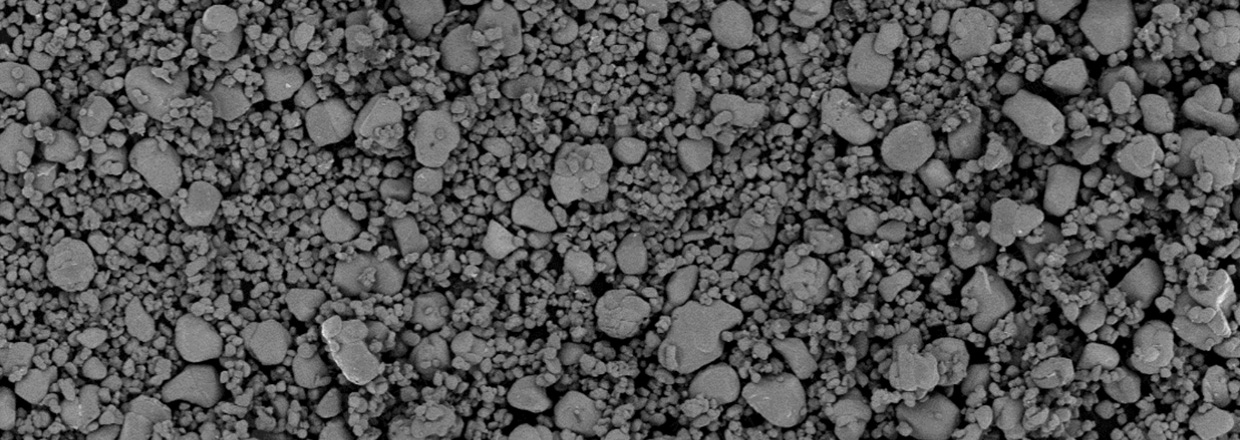

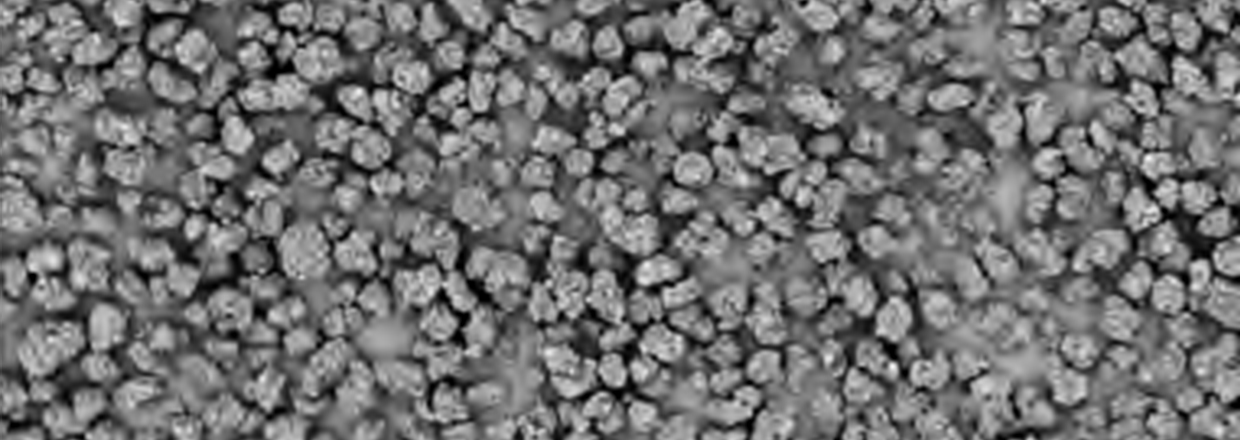

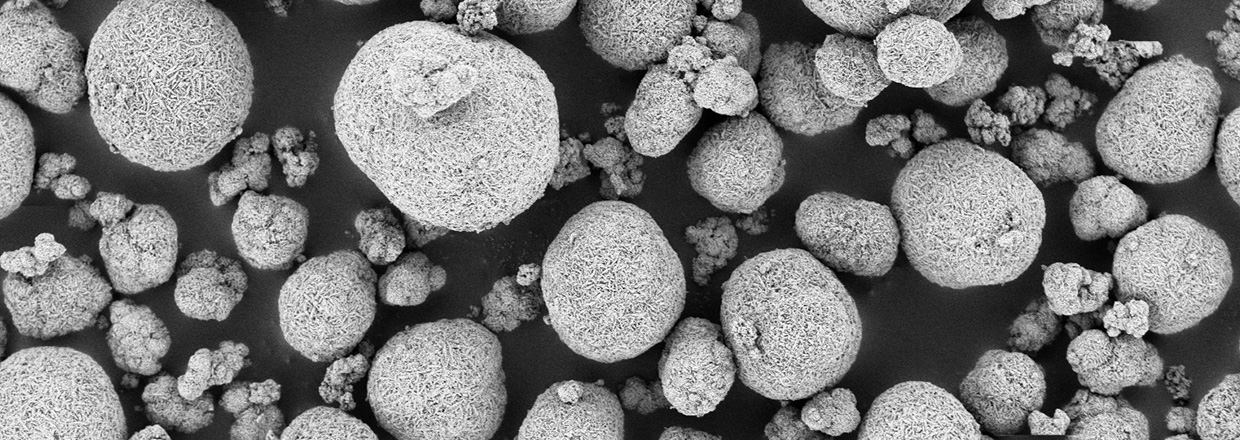

Recovered lithium iron phosphate

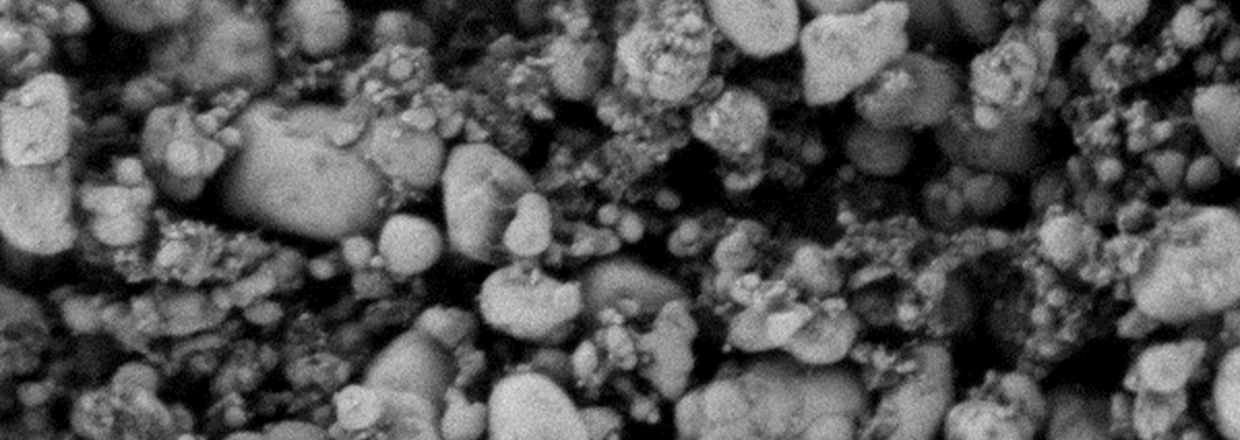

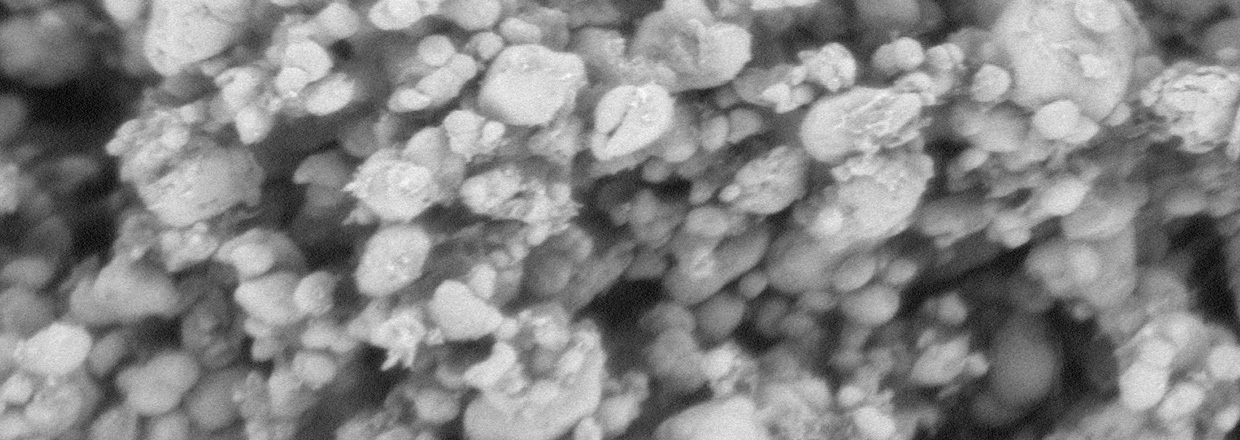

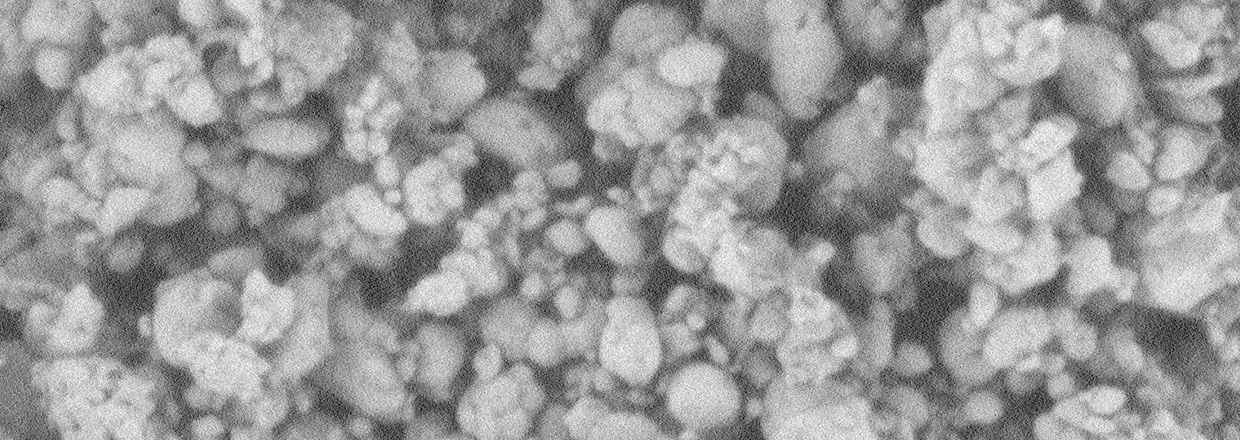

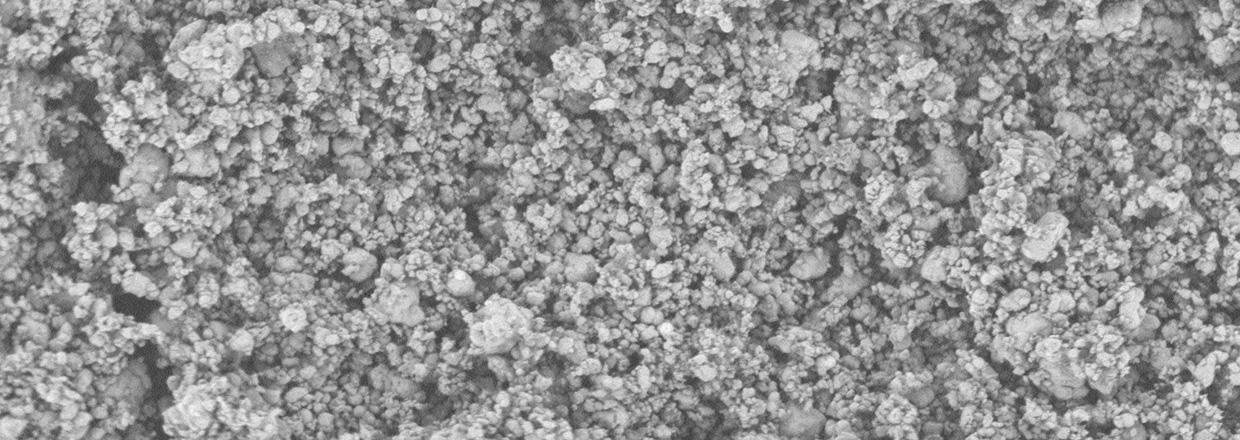

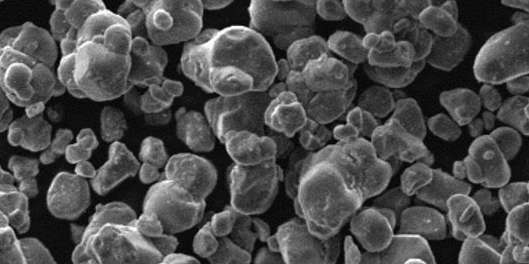

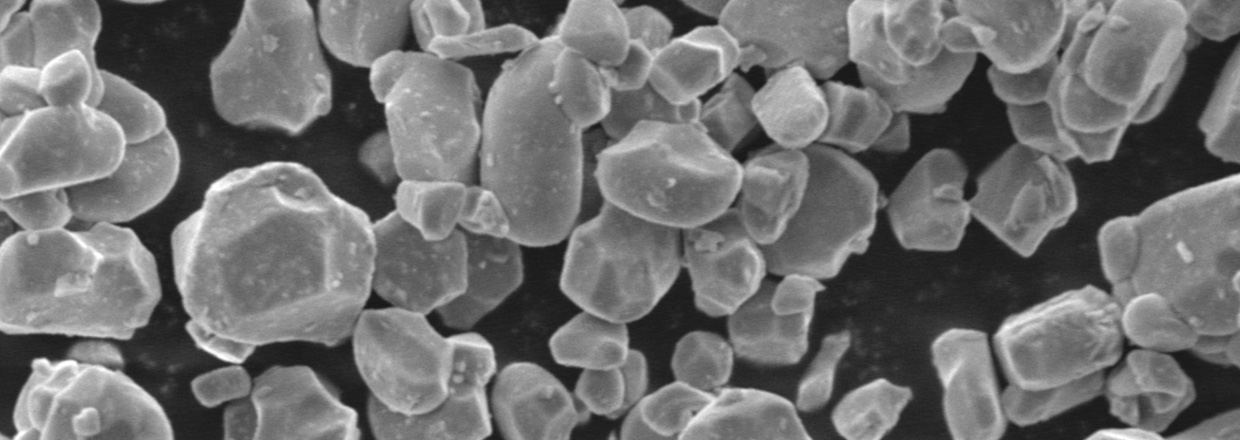

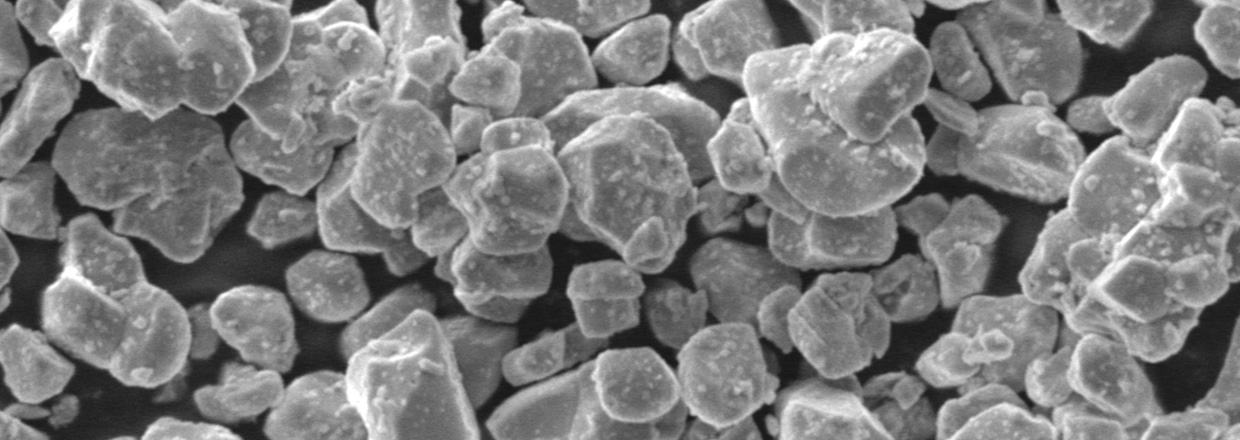

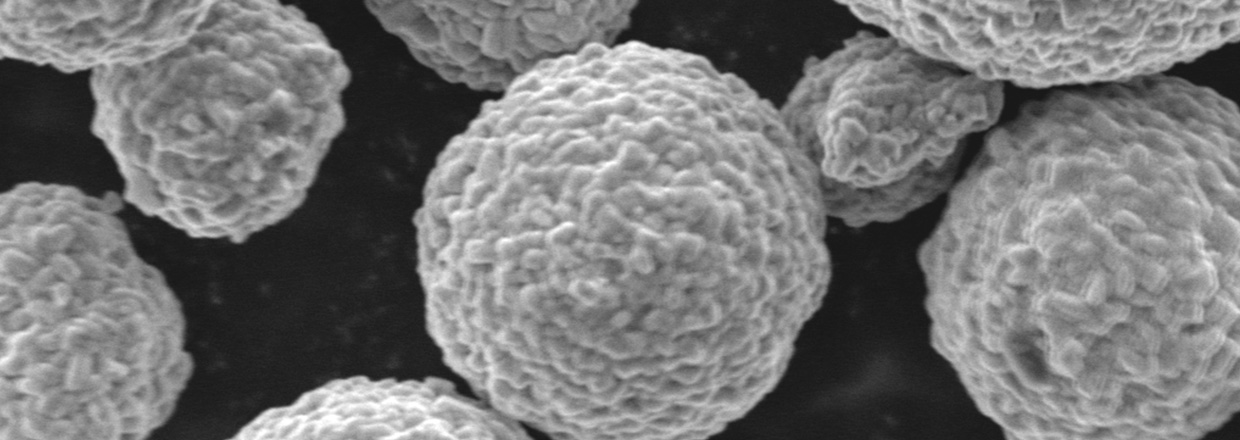

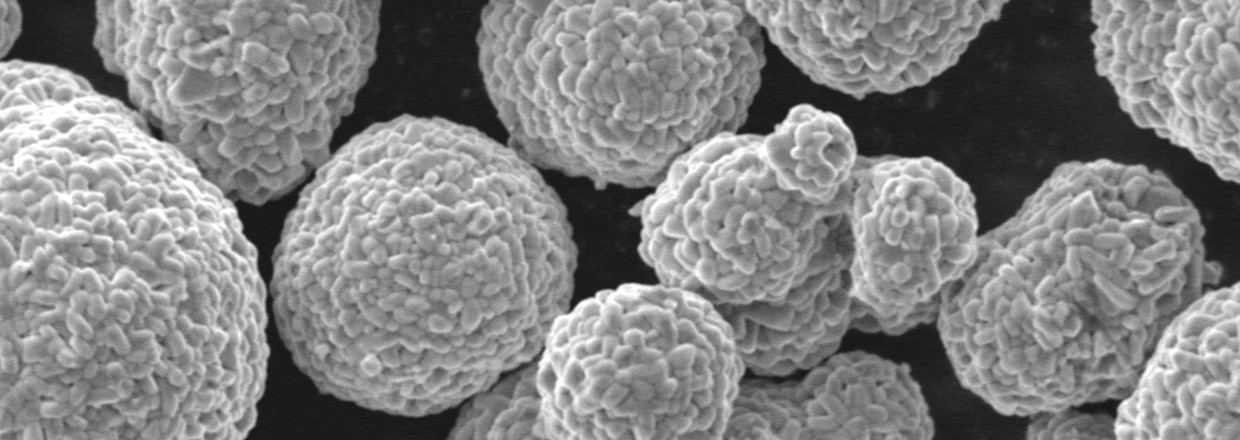

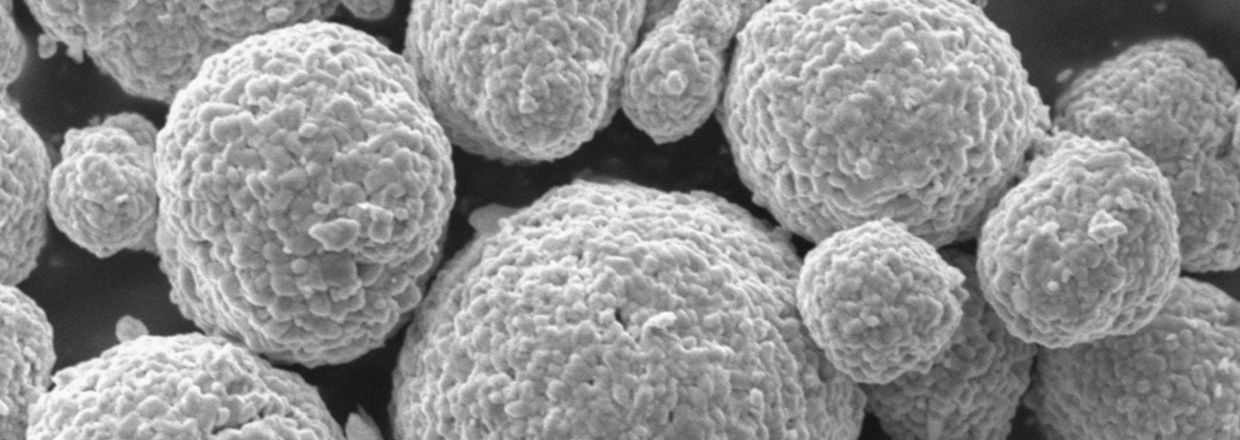

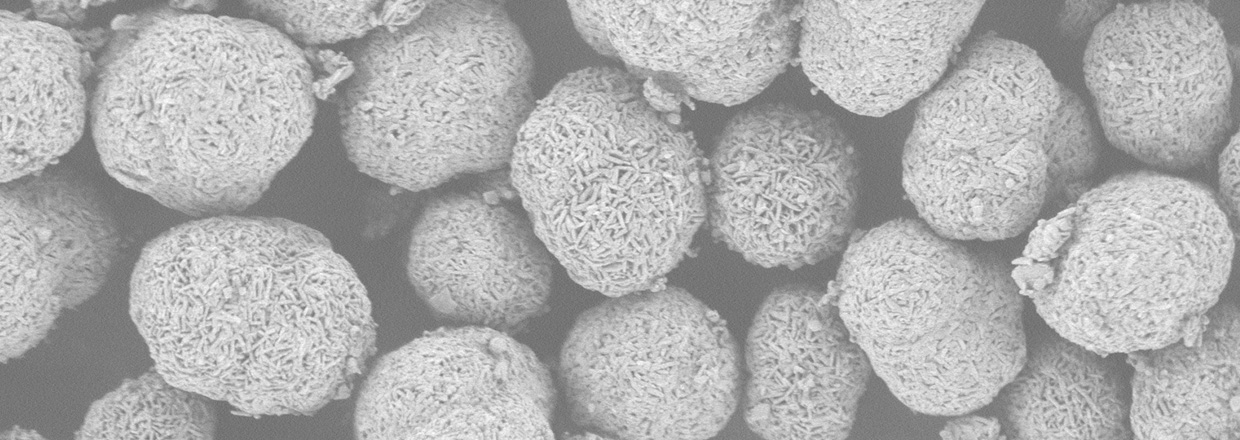

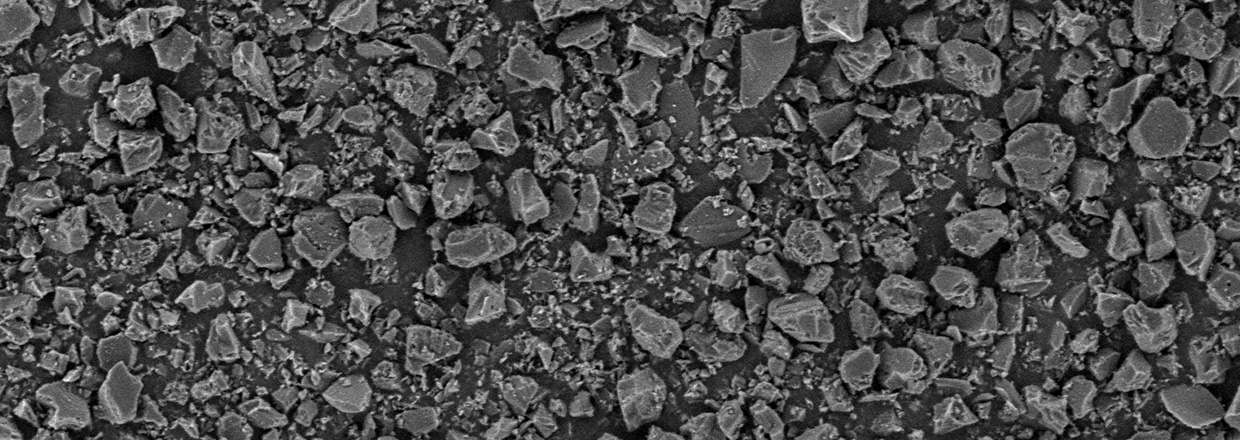

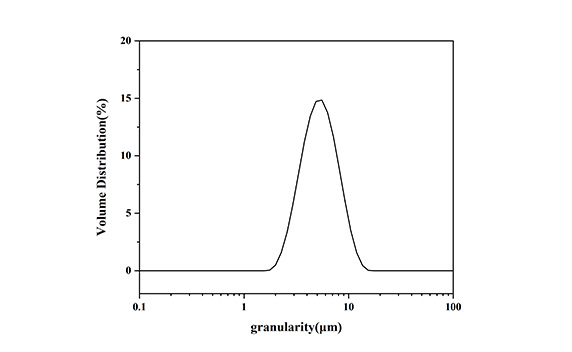

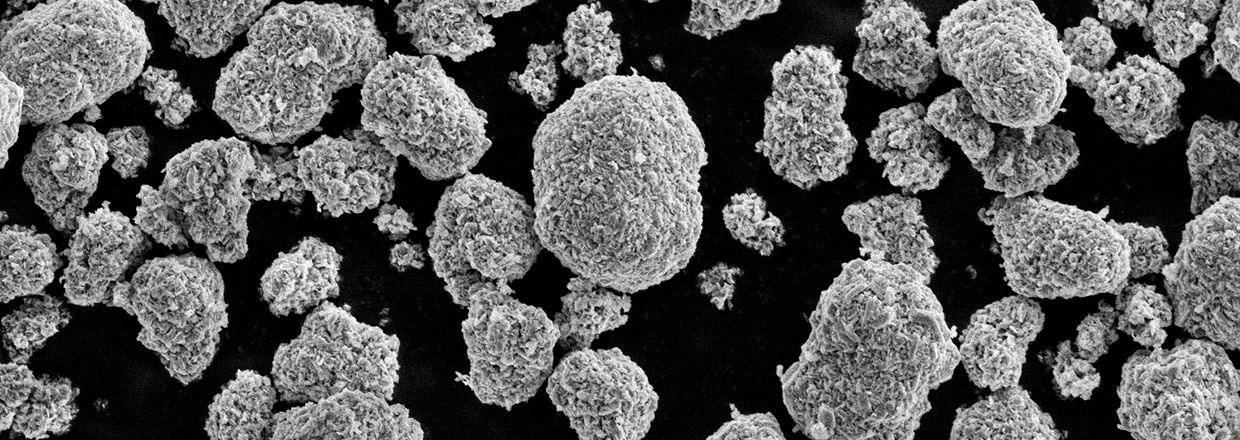

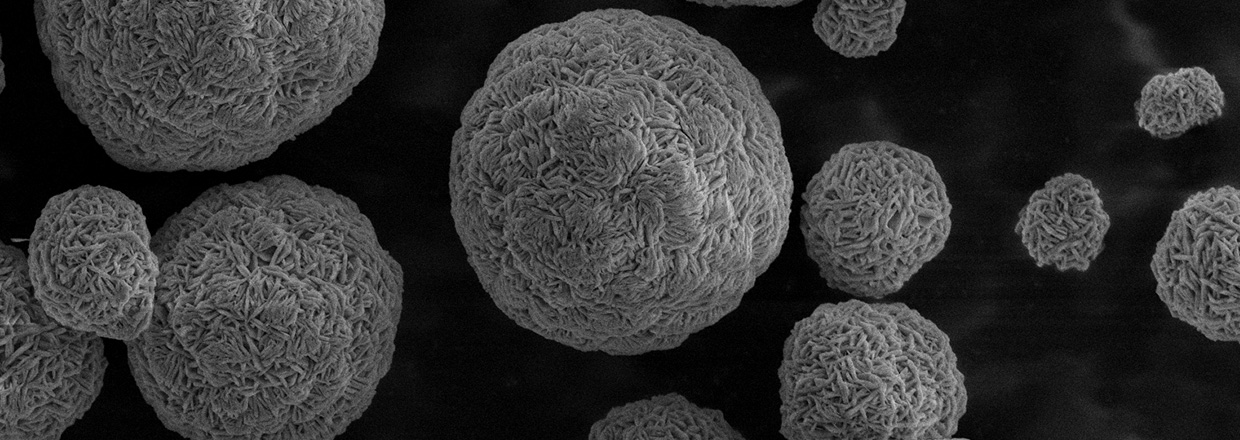

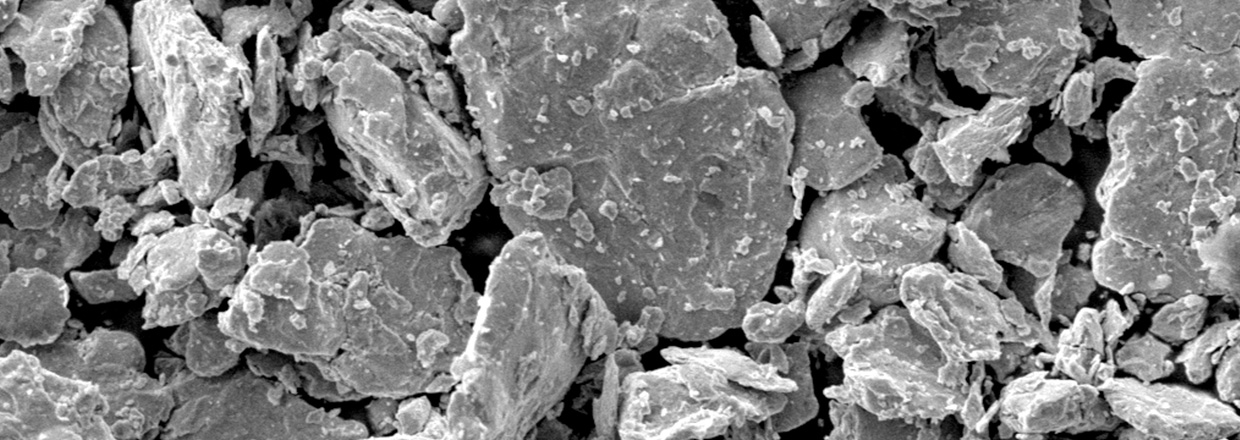

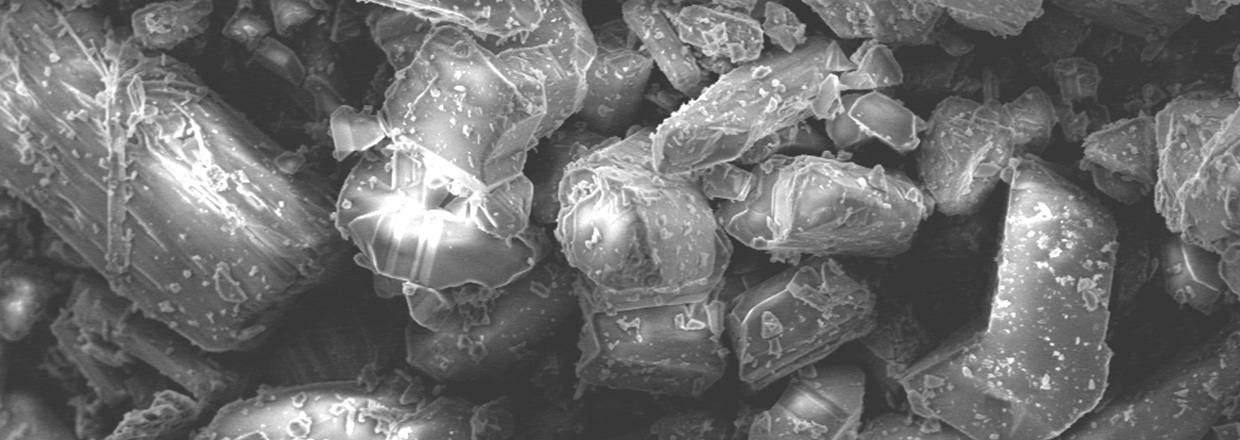

Recovered lithium iron phosphate has many advantages, and has become current popular cathode active material product of lithium battery. Brunp Recycling uses a high temperature solid-phase method to regenerate waste lithium iron phosphate, and get a recovered lithium iron phosphate product with characters of high compaction, high capacity, and stable plateau etc. The product has high energy density, strong stability, and low cost for raw materials, and simultaneously is a great response to national policies of environmental protection. Recycling and regenerating waste lithium iron phosphate reduces hazard to environment caused by battery pollution, shortens flow-path of powder preparation to create higher economical value and realize resource saving.

-

High compaction

-

High capacity

-

Stable plateau

-

Raw materials with low cost

-

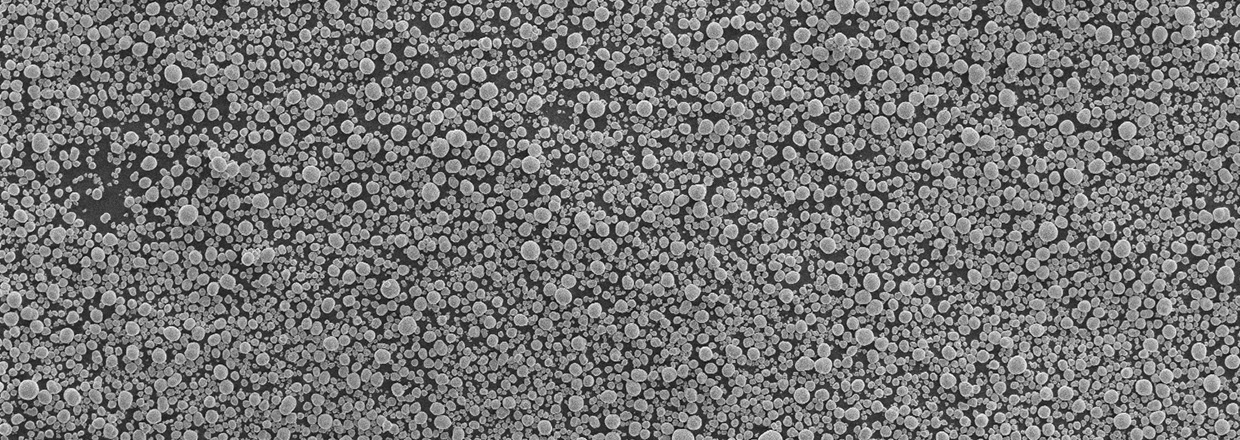

50000 x

-

≥2.35

Compaction density -3T (g/cm3)

-

<60.0

Powder resistivity (Ω•cm)

-

0.6-1.6

Dv50 (μm)

-

>157

Initial charge capacity per gram at 0.1 C (mAh/g)

-

>150

Initial discharge capacity per gram at 0.1 C (mAh/g)

-

>126

Initial discharge capacity per gram at 1 C (mAh/g)

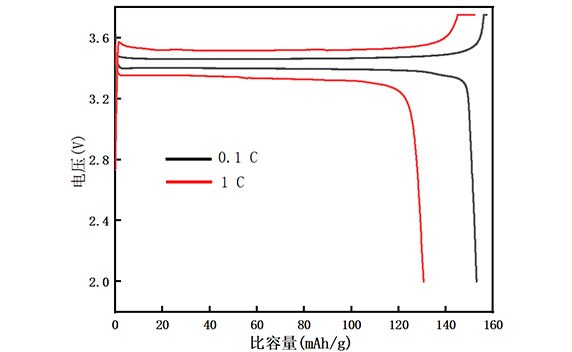

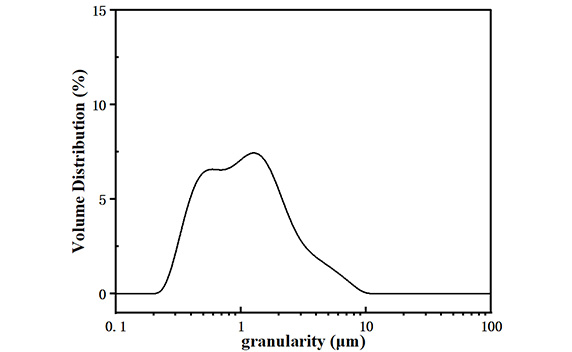

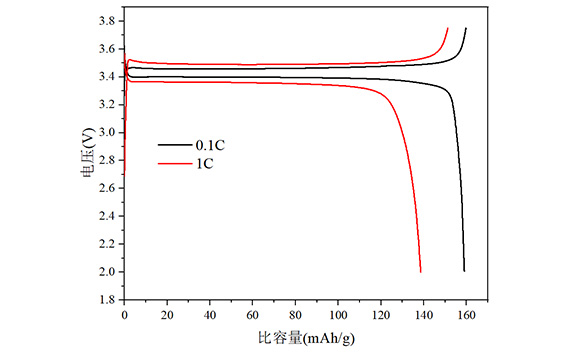

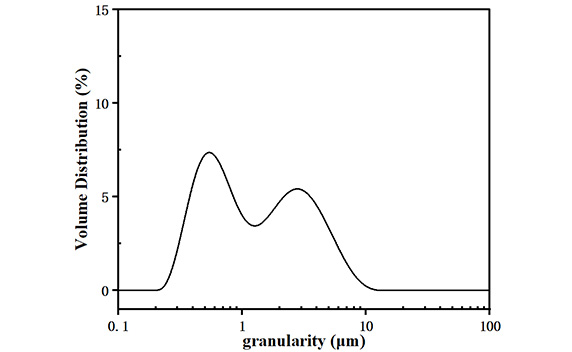

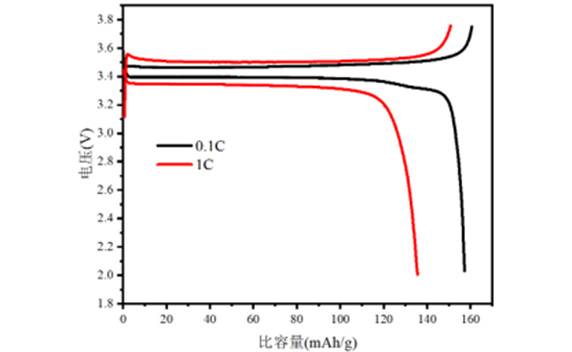

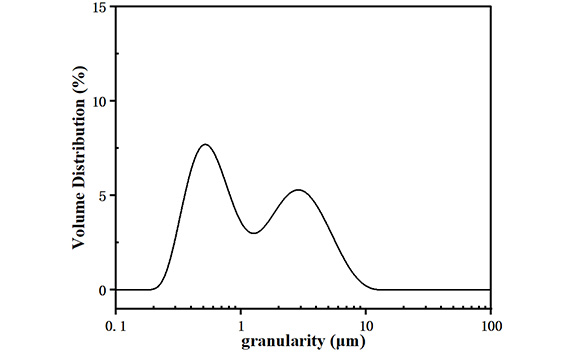

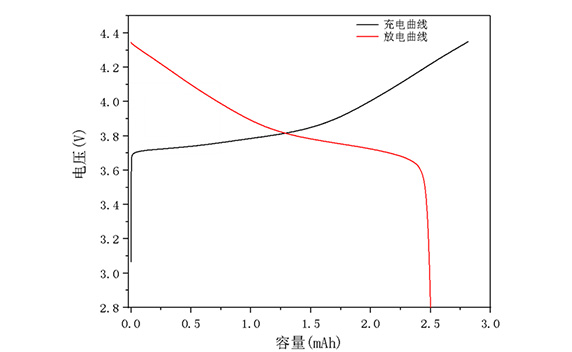

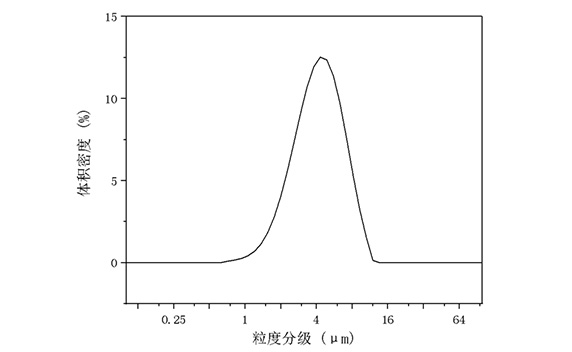

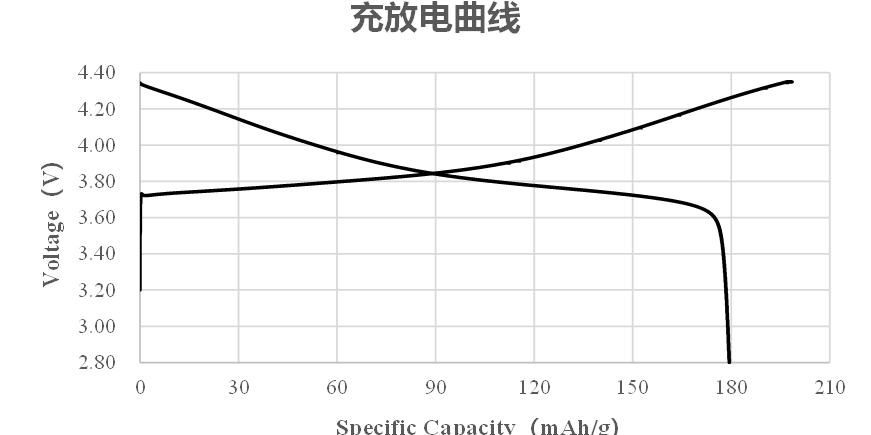

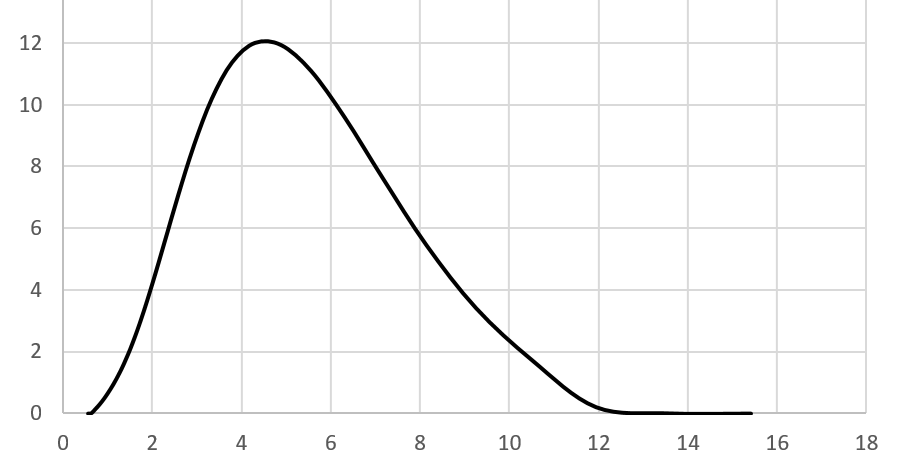

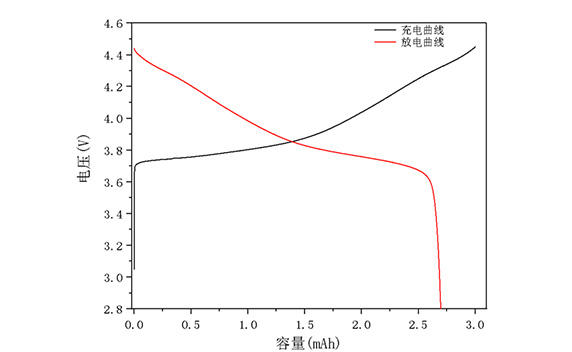

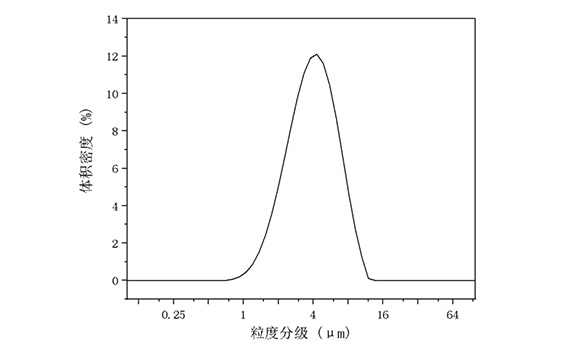

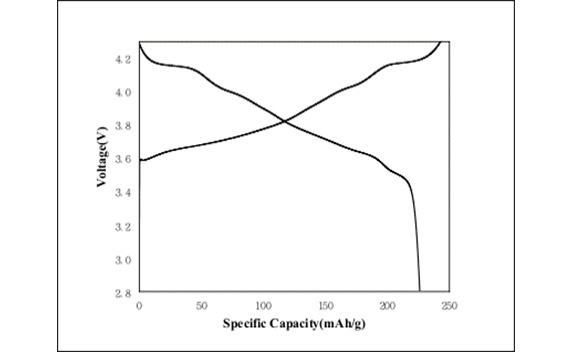

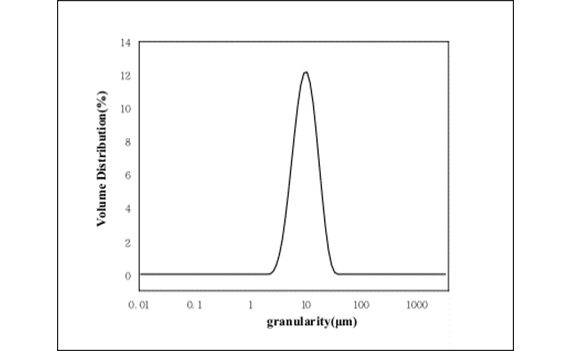

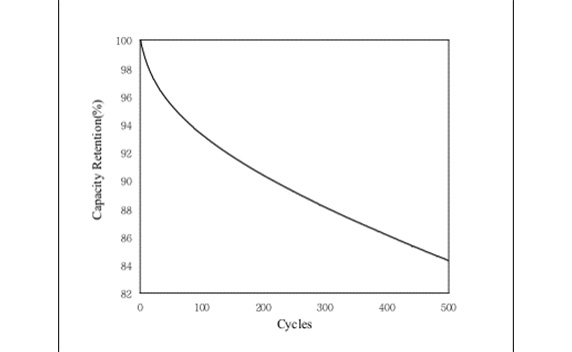

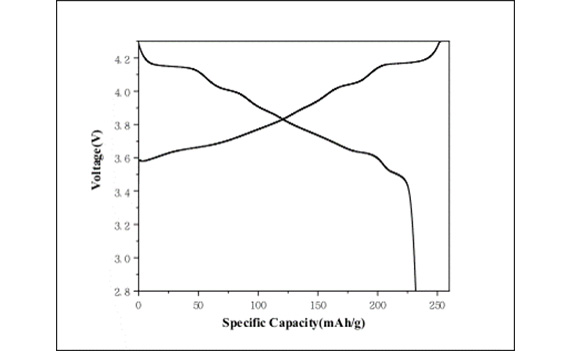

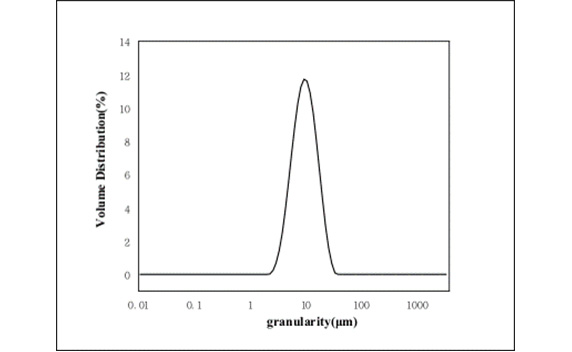

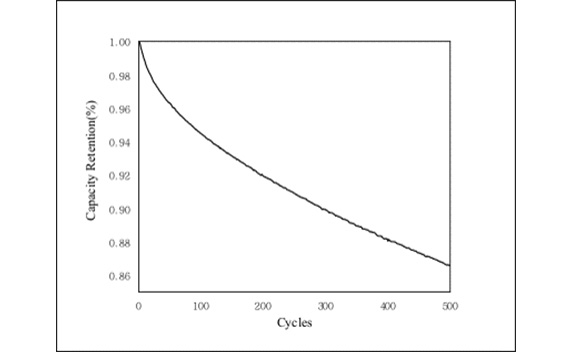

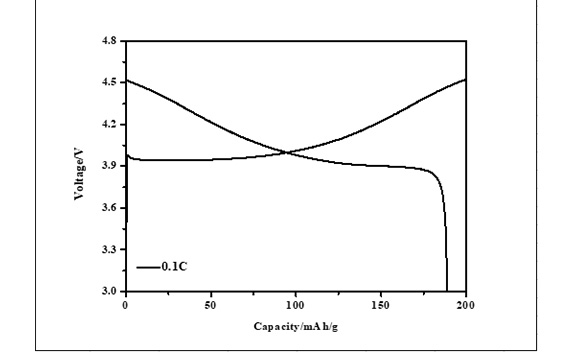

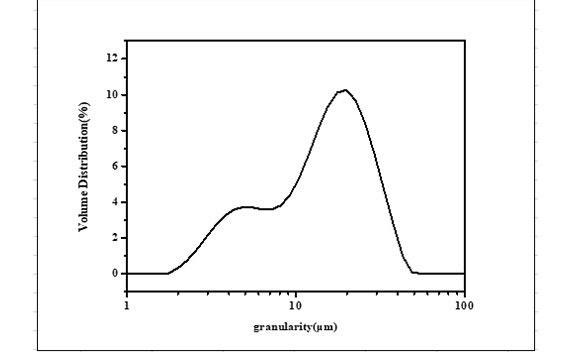

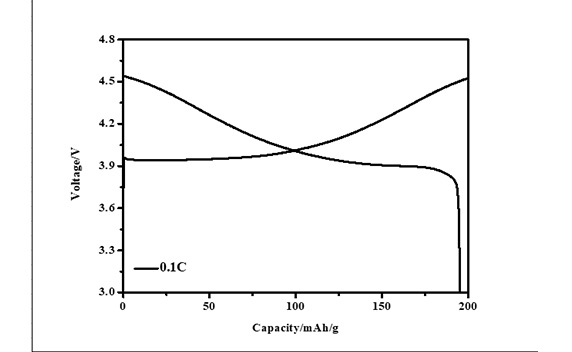

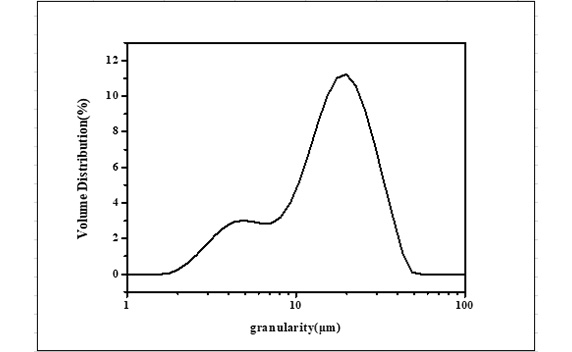

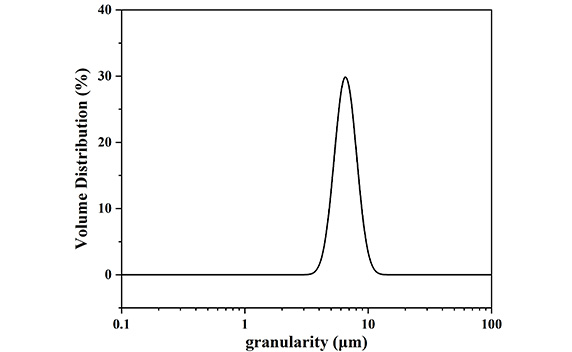

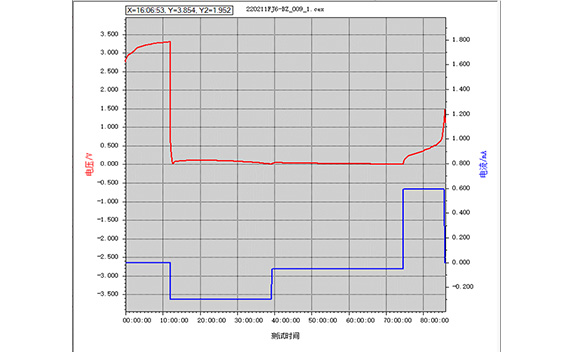

Technical Charts

-

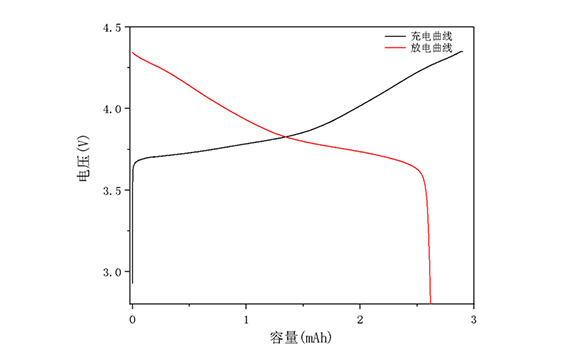

Graph of curve of charge and discharge

-

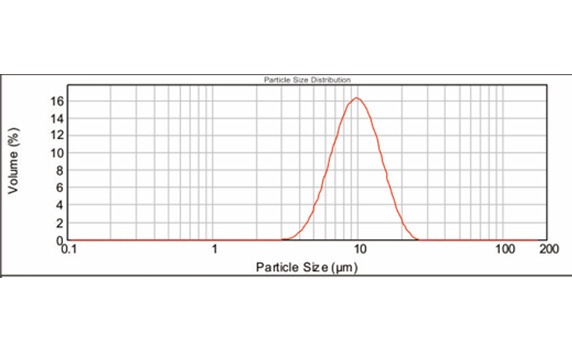

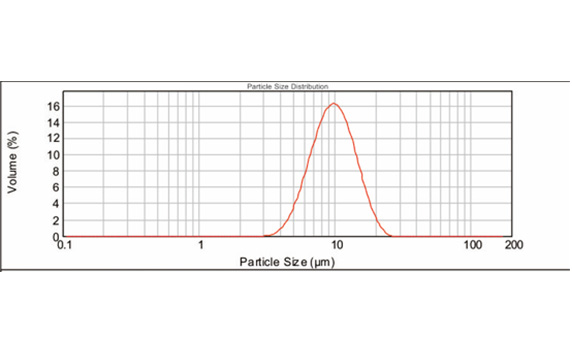

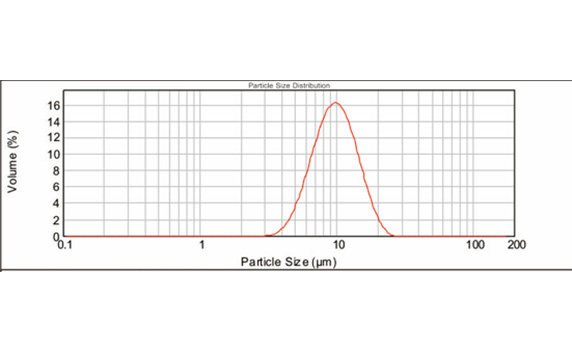

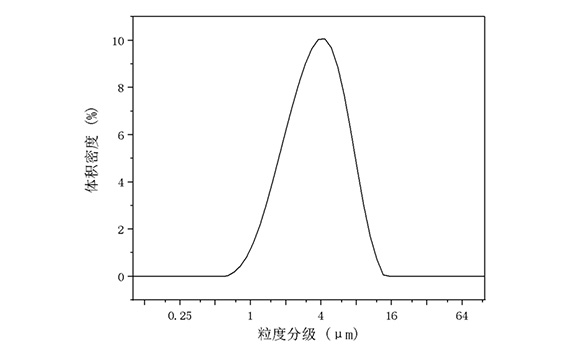

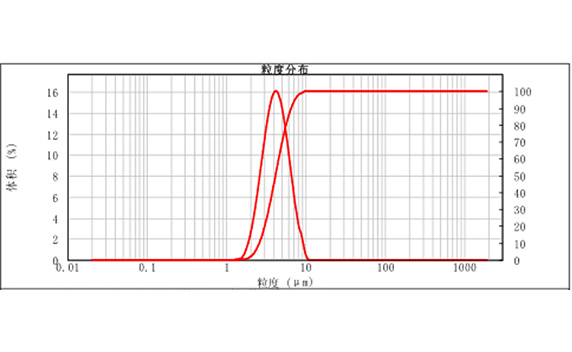

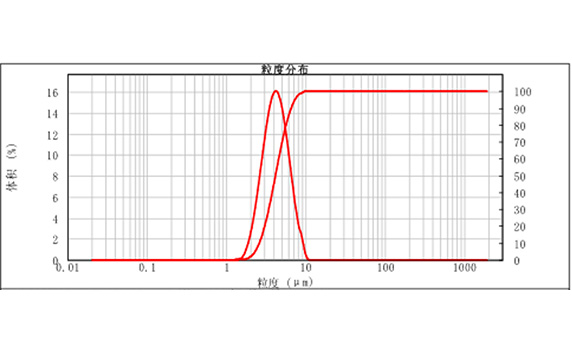

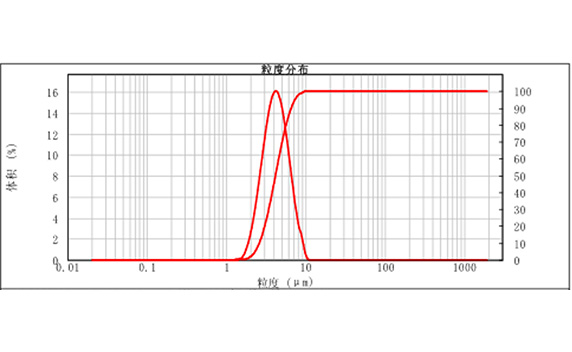

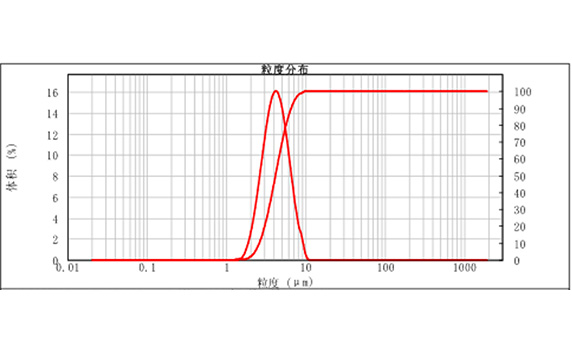

Graph of distribution of particle size

-

-

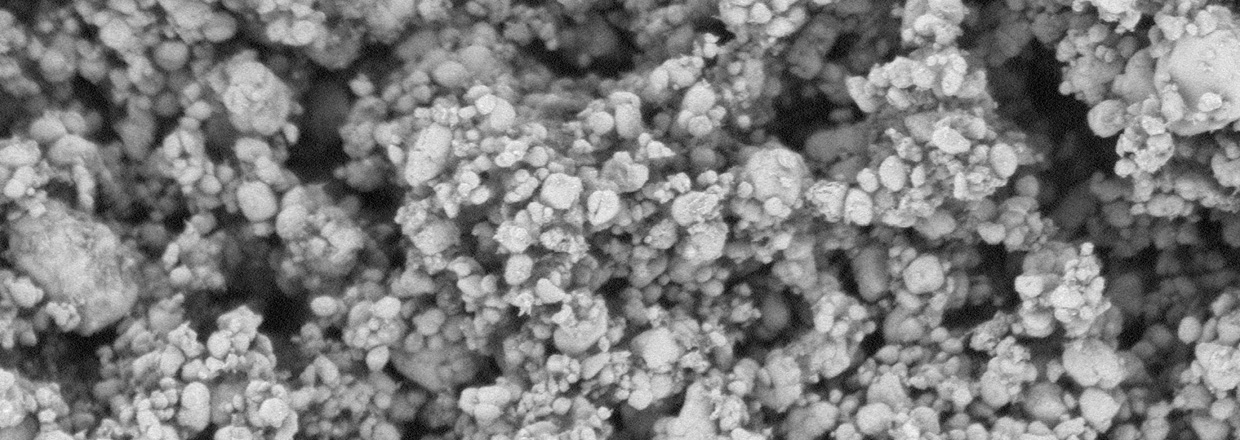

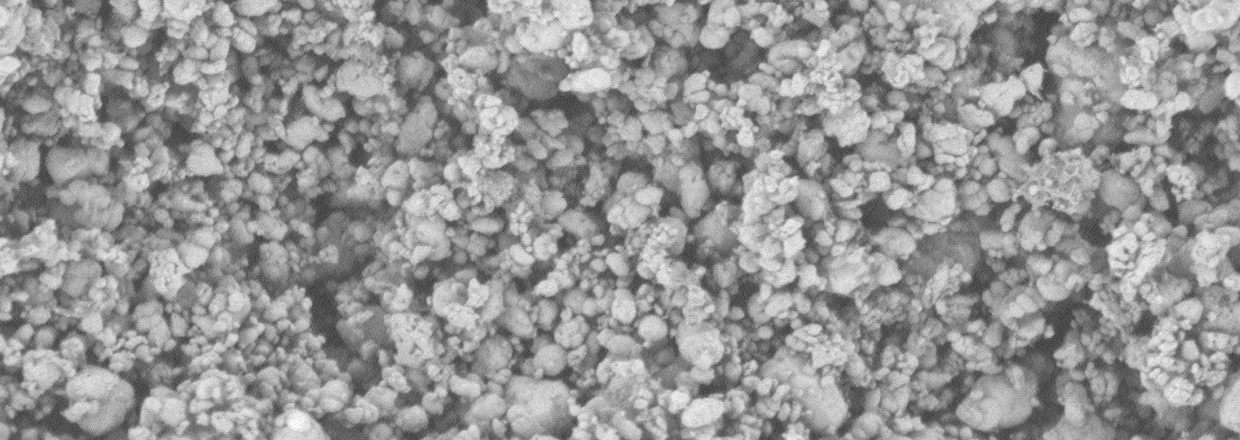

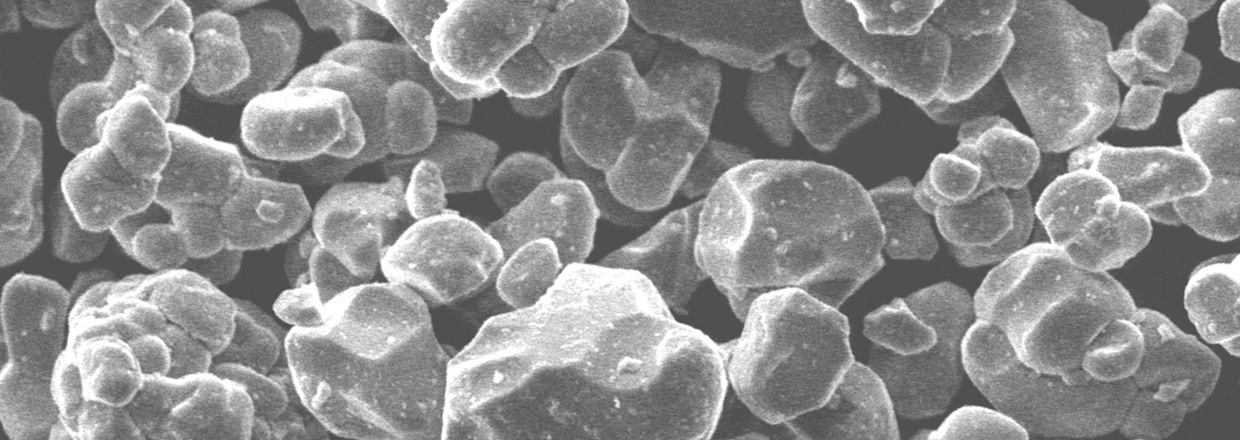

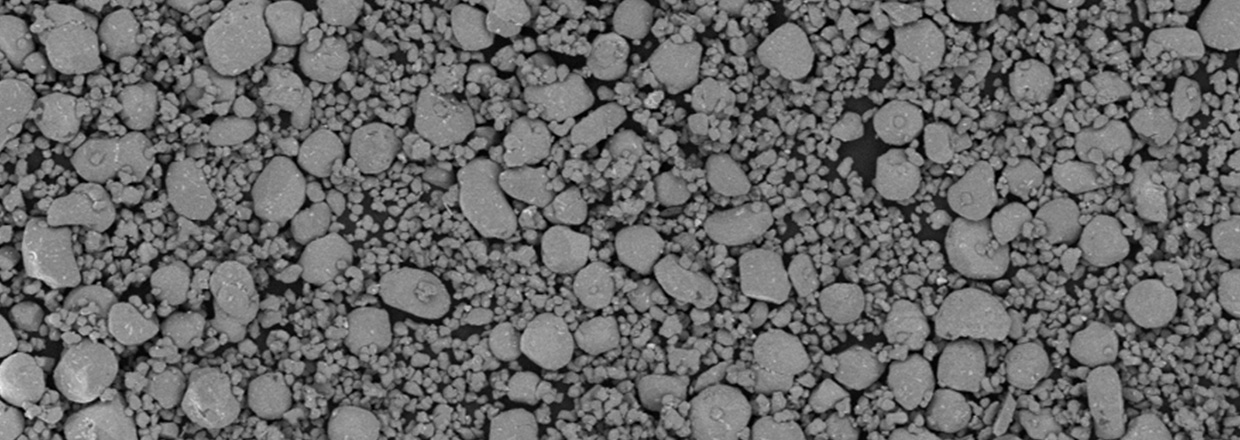

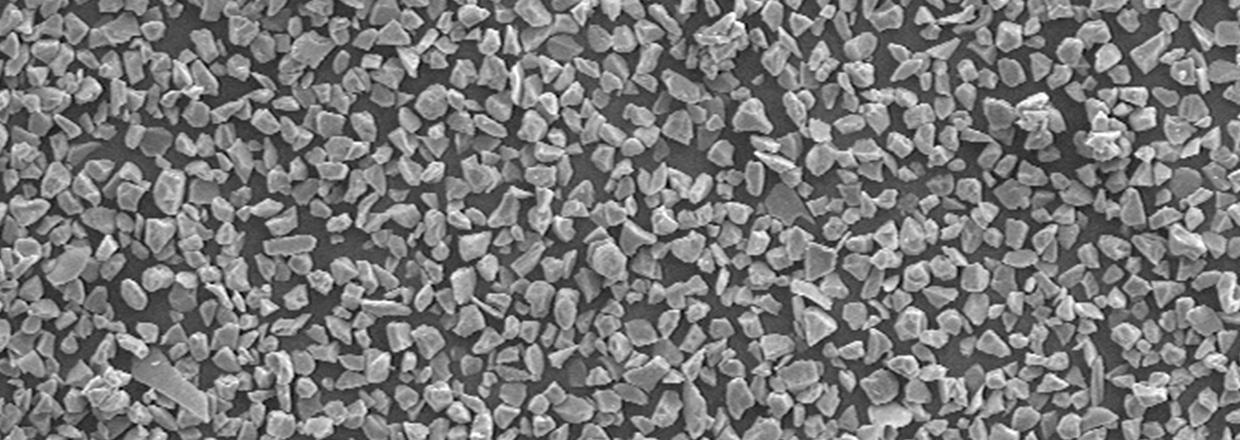

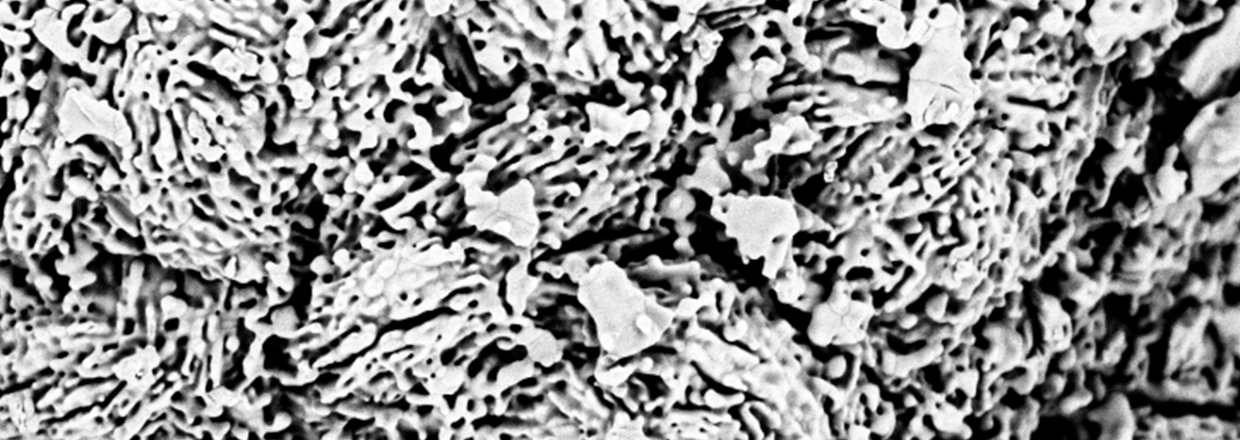

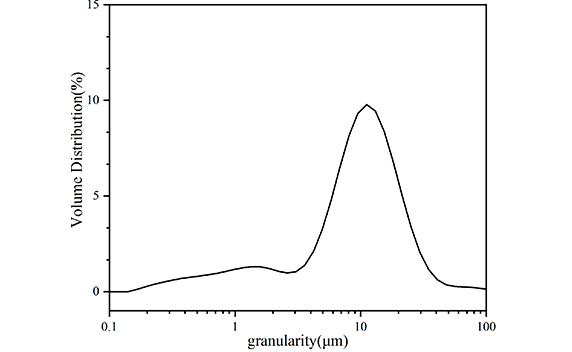

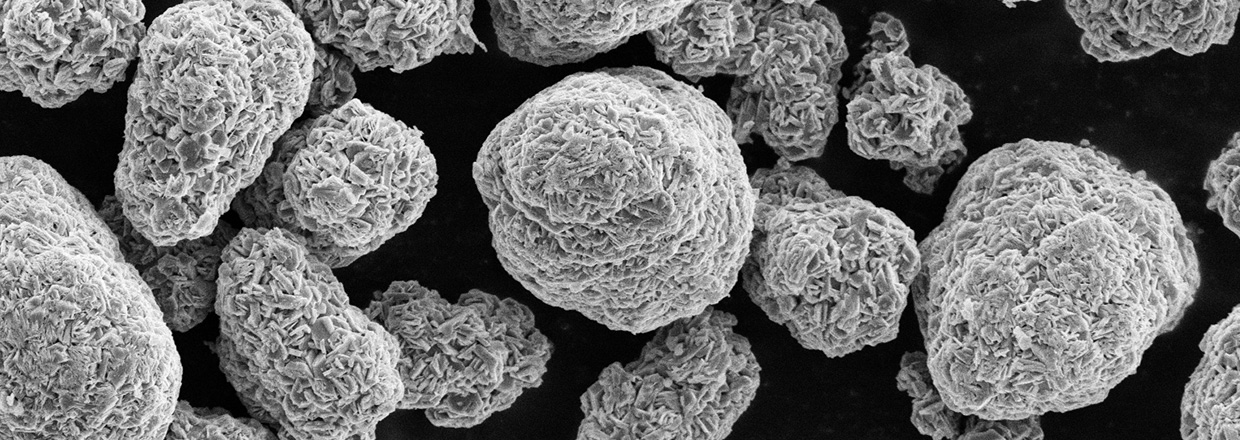

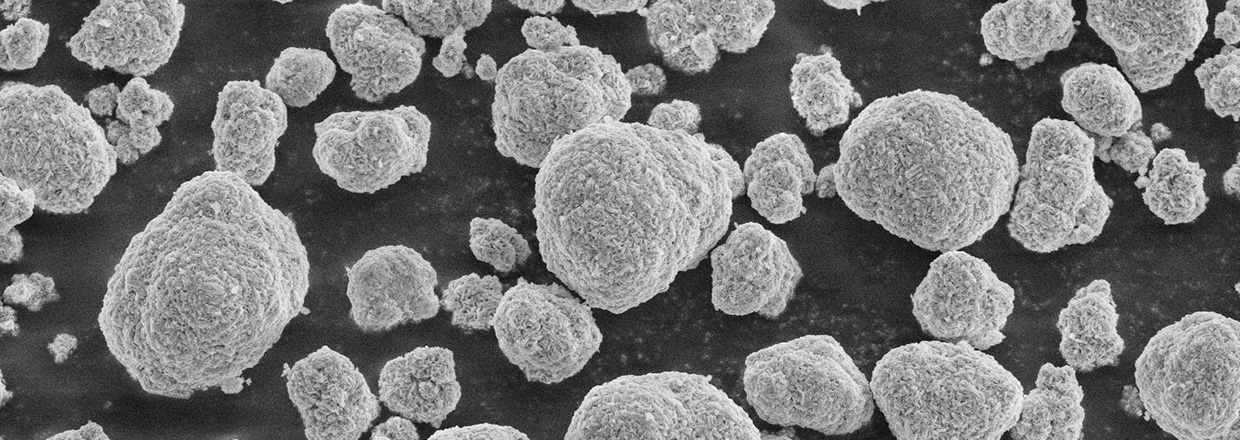

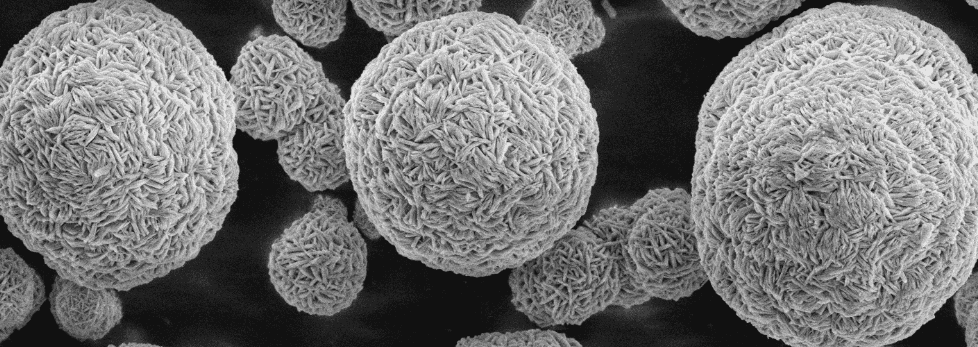

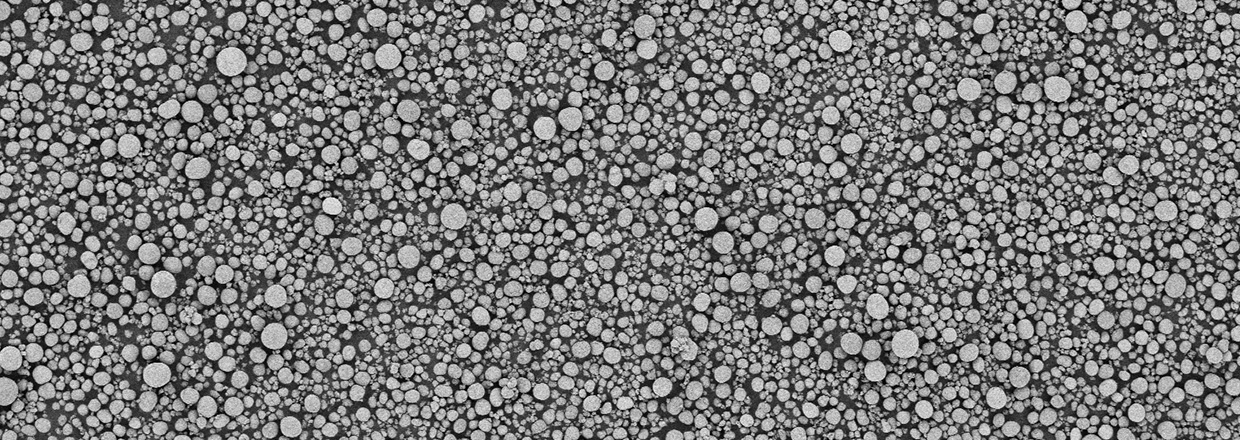

2nd-generation lithium iron phosphate

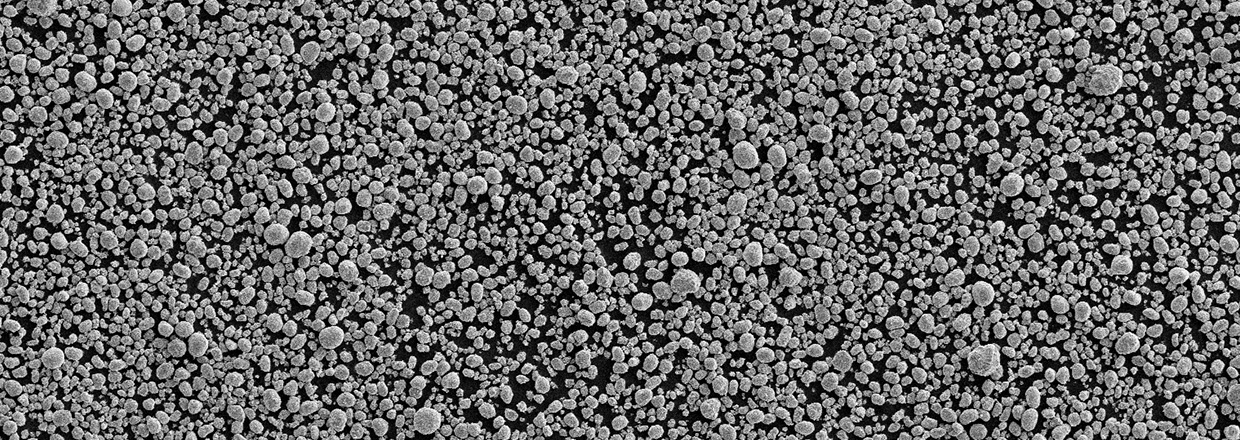

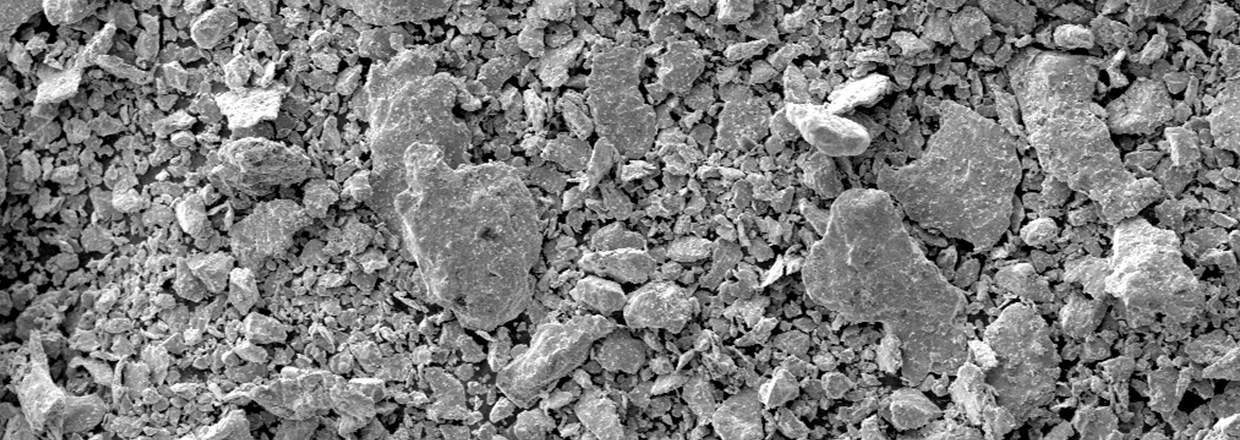

Lithium iron phosphate is currently popular cathode active material product of lithium battery. Brunp Recycling uses phosphorus and iron for synthesizing ferric phosphate, and makes creative development and transformation in directions of nanocrystallization of particles, and optimization of carbon coating etc. It has produced the 2nd-generation lithium iron phosphate with high compaction, high capacity, and stable plateau. Moreover, its present product has many advantages including high capacity per gram, high energy density, high safety, environmental friendliness, and low cost of raw materials, satisfying requirement of high endurance mileage while taking cost control into account.

-

High capacity per gram

-

High energy density

-

High safety

-

Environmental friendliness

-

Low cost of raw materials

-

50000 x

-

20000 x

-

≥2.38

Compaction density -3T (g/cm3)

-

<60.0

Powder resistivity (Ω•cm)

-

0.7~1.7

Dv50 (μm)

-

>160

Initial charge capacity per gram at 0.1 C (mAh/g)

-

>156

Initial discharge capacity per gram at 0.1 C (mAh/g)

-

>138

Initial discharge capacity per gram at 1 C (mAh/g)

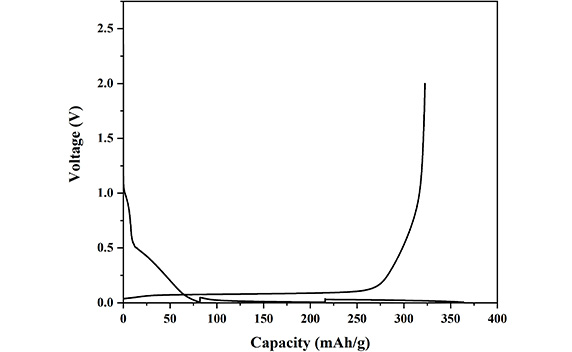

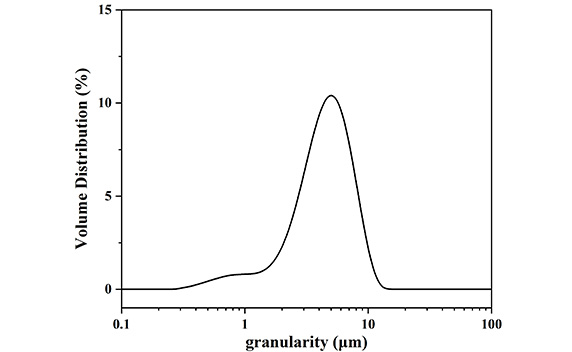

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

-

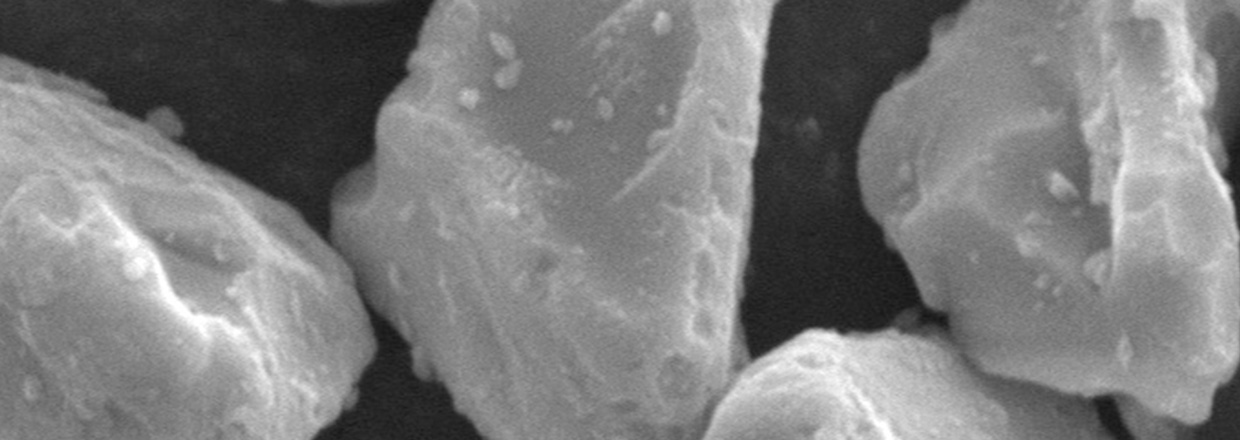

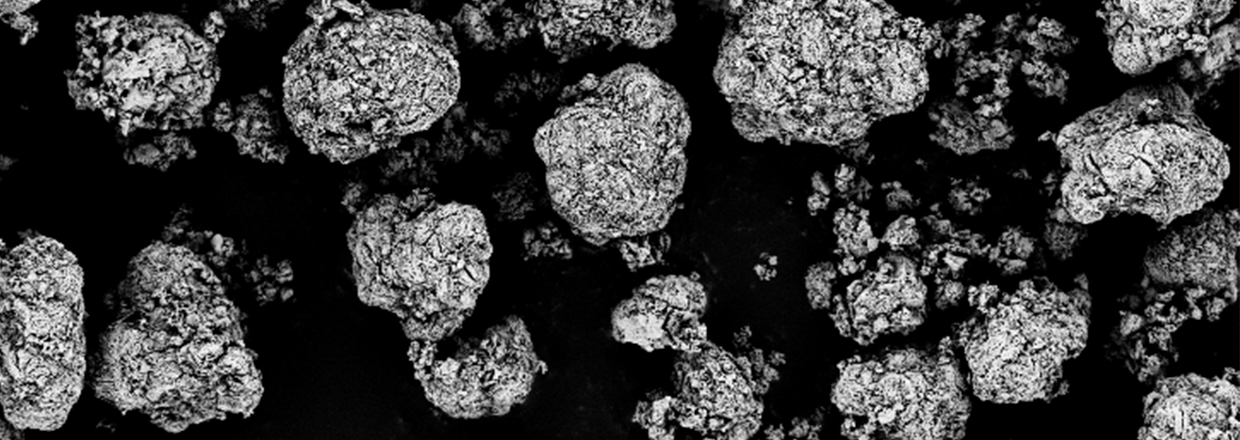

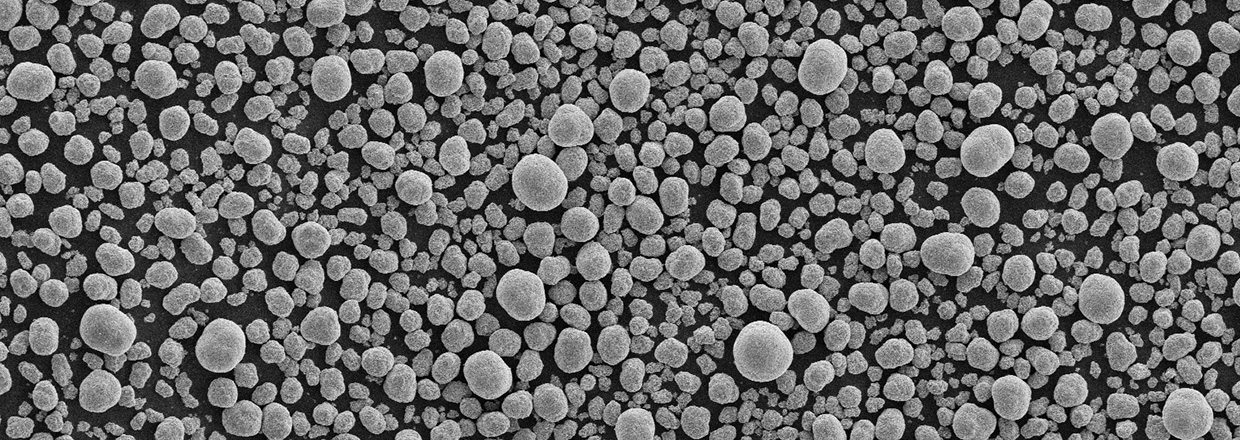

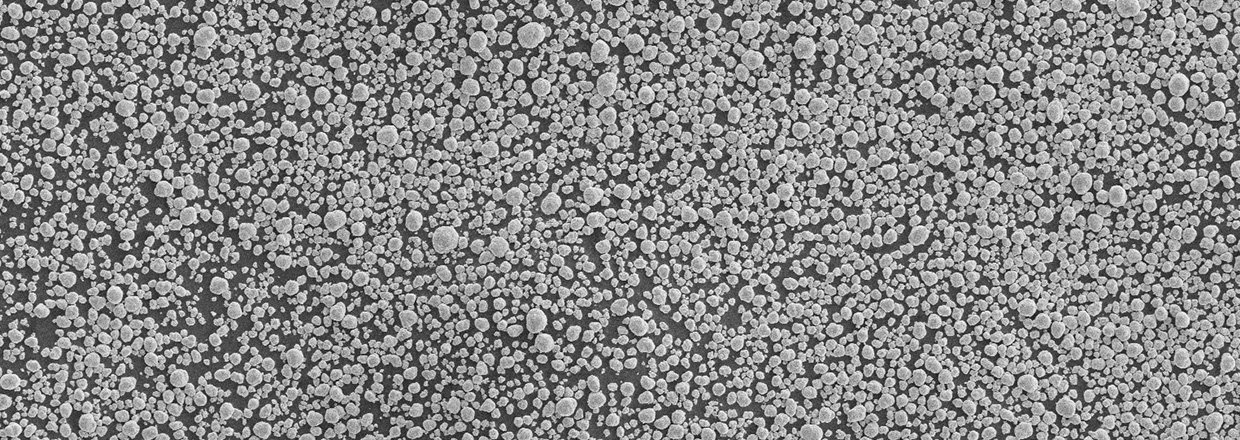

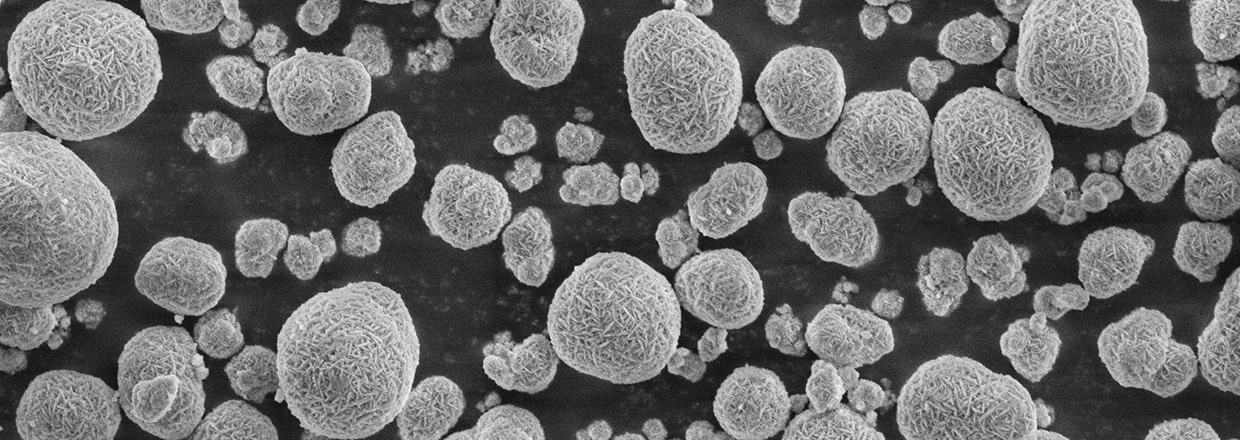

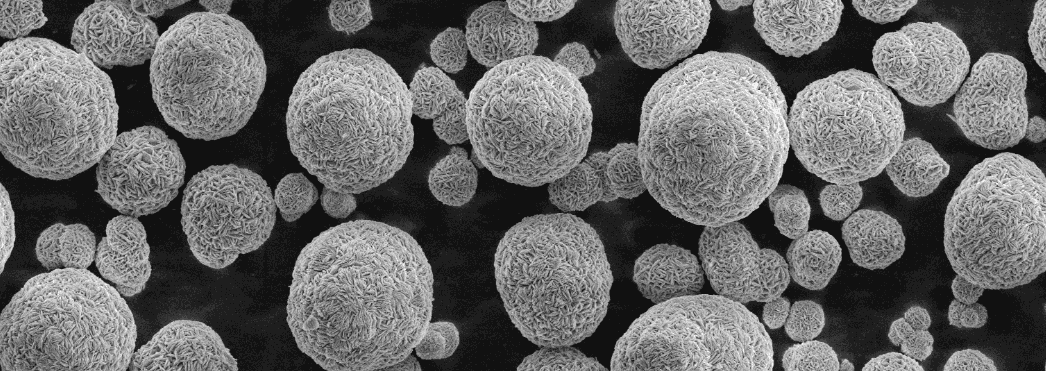

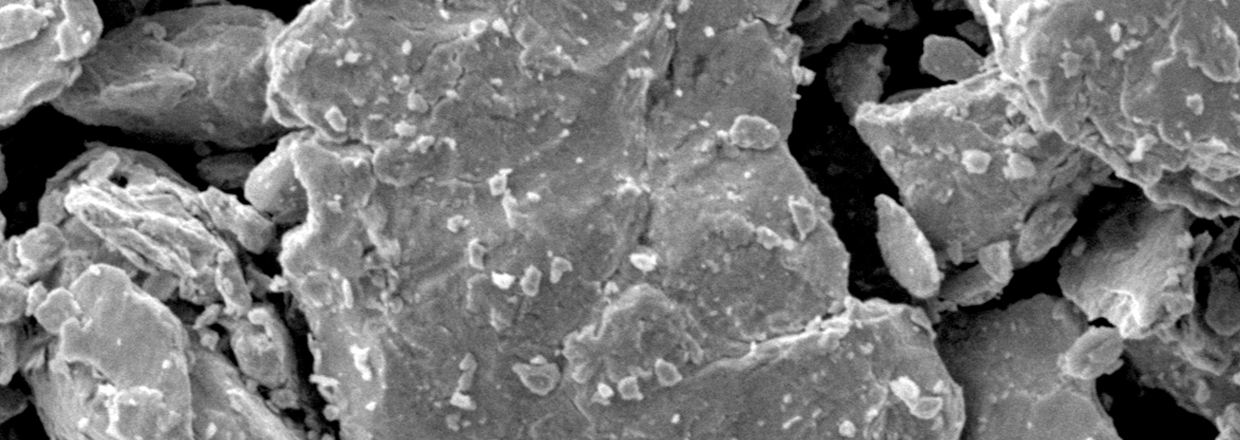

3rd-generation lithium iron phosphate

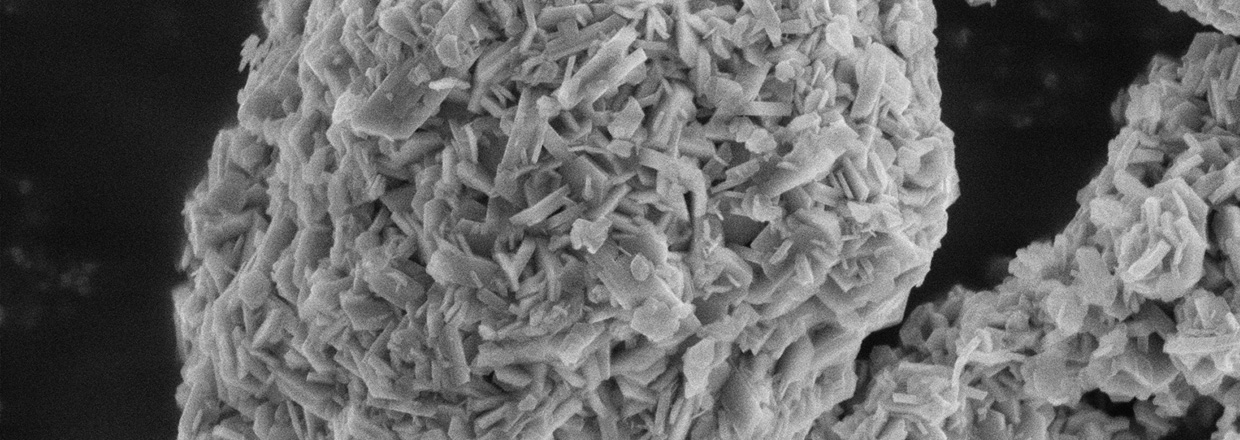

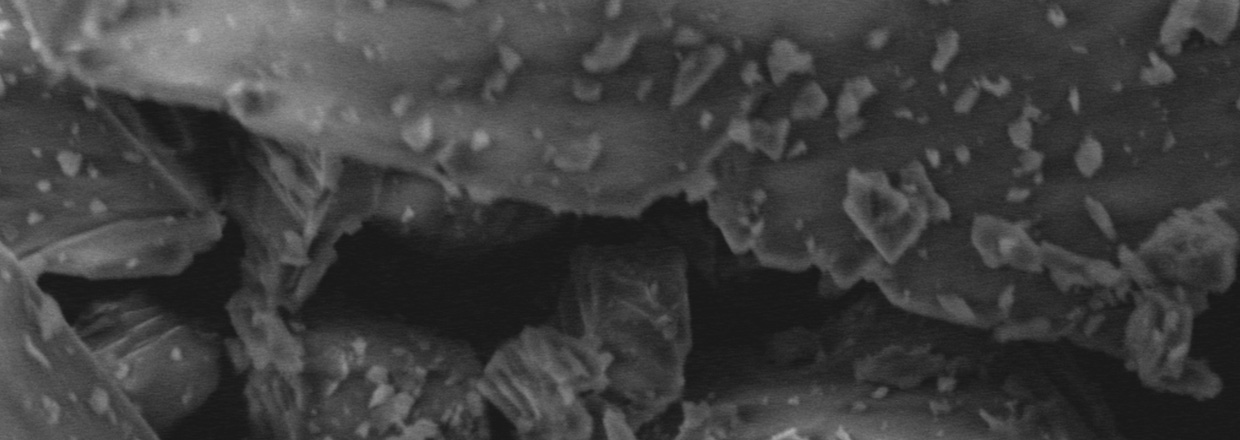

Lithium iron phosphate is currently popular cathode active material product of lithium battery. Brunp Recycling uses hydrometallurgy for synthesizing ferric phosphate, and further synthesizes 3rd-generation lithium iron phosphate by means of carbon coating, element doping, and optimization of particle size etc. Its present product has typical features of high compaction, high safety and high stability, with multiple advantages including long cycle life, high safety, environmental friendliness, wide source of raw materials and low cost

-

Long cycle life

-

High safety

-

Environmental friendliness

-

Wide source of raw materials

-

50000 x

-

20000 x

-

10000 x

-

≥2.48

Compaction density -3T (g/cm3)

-

<60.0

Powder resistivity (Ω•cm)

-

0.7~1.7

Dv50 (μm)

-

159.0~165.0

Initial charge capacity per gram at 0.1 C (mAh/g)

-

155.0~161.0

Initial discharge capacity per gram at 0.1 C (mAh/g)

-

>128

Initial discharge capacity per gram at 1 C (mAh/g)

Technical Charts

-

Charge and discharge capacity

-

Graph of particle size

-

-

LL5503

-

LL5525

-

LL6007

-

LL6510

-

LL8203

-

LL8313

-

LL9203

-

LL9403

-

LL5503

LL5503 is applied at a voltage of 4.35 V, and is one of the key cathode active materials of lithium-ion battery firstly applied in a scene of traction battery for vehicle. LL5503 has long cycle life, high energy density, high safety, high voltage, strong thermostability, and high cost-effectiveness. Based on the 1st-generation low-cobalt material, Brunp Recycling creates the 2nd-generation low-cobalt monocrystal material product by further control of cobalt content, reduces the cost of material obviously, and takes the lead in achieving mass production in the whole industry. Now this product becomes the “king of high cost-effectiveness of low-cobalt material”, is widely applied in a field of traction transportation.

-

Long cycle life

-

High energy density

-

High safety

-

High voltage

-

Strong thermostability

-

High cost-effectiveness

-

10000 x

-

3.60-4.60

D50(μm)

-

0.50-0.78

BET(m2/g)

-

32.70-33.90

Ni(wt%)

-

6.80-8.00

Co(wt%)

-

17.90-19.10

Mn(wt%)

-

177.0-182.0

Initial specific discharge capacity (mAh/g) (2.8-4.35 V, at 0.1 C)

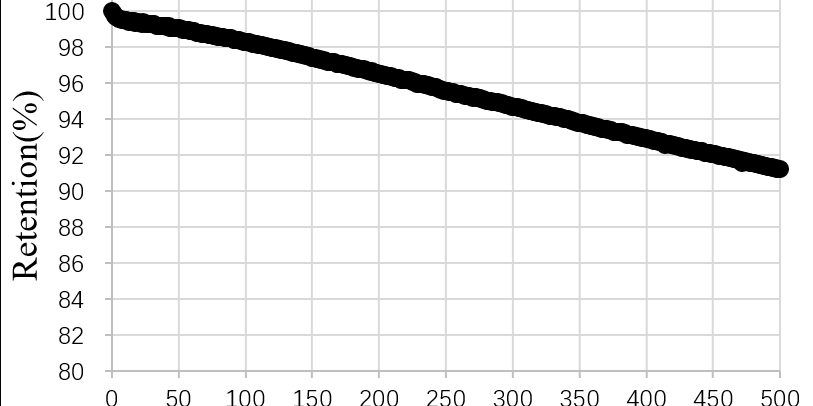

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of distribution of particle size

-

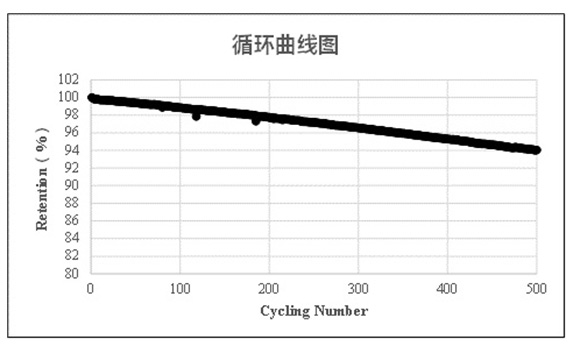

Graph of cycle performance

-

-

LL5525

LL5525 is another innovative product based on extremely low-cobalt 3rd-generation low-cobalt monocrystal LL5515 material of Brunp, subversively solves a problem of DCR in low-cobalt system, and obviously improves DCR and cycle performance compared with the previous generation material, which can be applied in working voltages of 4.35 V/4.4 V. This product has typical advantages of long cycle life, high energy density, high safety, high voltage, strong thermostability, high cost-effectiveness and environment protection etc. Currently, this product has been widely applied in a field of traction transportation, and is an important raw material for preparing a battery pack for new energy vehicles.

-

Long cycle life

-

High energy density

-

High safety

-

High voltage

-

Strong thermostability

-

High cost-effectiveness

-

10000 x

-

3.80-4.60

D50(μm)

-

0.68-0.92

BET(m2/g)

-

32.80-34.20

Ni(wt%)

-

3.35-4.05

Co(wt%)

-

21.00-22.50

Mn(wt%)

-

183.0-189.0

Initial specific discharge capacity (mAh/g) (2.8-4.5 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of distribution of particle size

-

Graph of cycle performance

-

-

LL6007

LL6007 is applied at a voltage of 4.4 V, and is a further upgrade based on a ternary cathode active material at a high voltage of 4.35 V. Brunp Recycling successfully realizes a stable structure of the material at high voltage by a special doping process. LL6007 has long cycle life, high energy density, good safety, high voltage, strong thermostability, and high cost-effectiveness, has now been widely applied in a field of traction transportation, and is an important material for preparing a battery of new energy vehicles.

-

Long cycle life

-

High energy density

-

High safety

-

High voltage

-

Strong thermostability

-

High cost-effectiveness

-

10000 x

-

3.50-4.50

D50(μm)

-

0.62-0.81

BET(m2/g)

-

35.00-38.40

Ni(wt%)

-

2.75-3.30

Co(wt%)

-

18.30-20.70

Mn(wt%)

-

193.5-196.5

Initial specific discharge capacity (mAh/g) (2.8-4.45 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of distribution of particle size

-

Graph of cycle performance

-

-

LL6510

LL6510 is a ternary cathode active material at a high voltage of 4.35 V, and involves a process with lithium carbonate. Techonical modes are flexibly switched innovatively with reference to fluctuation in market price of lithium salts used as raw materials, and so the risk assosiated market price is relieved by the advanced technologies accordingly. LL6510 has long cycle life, high energy density, high safety, high voltage, strong thermostability, high cost-effectiveness, and environmental friendliness, has been widely applied in a field of traction transportation, is an important material for preparing a battery of new energy vehicles.

-

Long cycle life

-

High energy density

-

High safety

-

High voltage

-

Strong thermostability

-

High cost-effectiveness

-

10000 x

-

3.40-4.10

D50(μm)

-

0.83-1.12

BET(m2/g)

-

37.65-40.80

Ni(wt%)

-

3.80-4.60

Co(wt%)

-

14.8-16.4

Mn(wt%)

-

188.0-193.0

Initial specific discharge capacity (mAh/g) (2.8-4.35 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

Graph of cycle performance

-

-

LL8203

LL8203 is a 2nd-generation 8-series polycrystal material, for which wo-stage sintering process has been adopted, and a process of ultralong kiln has been innovatively utilized, promoting the ultralong kiln technology to realize breakthrough of the industry, and leading creative revolution of production process in the industry. LL8203 is a cathode active material with ultra-high energy density, and ultra-high cycle stability, whose safety meets all standards. Currently, it is mainly applied in transportation traction field including new energy vehicles with long endurance mileage, and is supplied to CATL and the like high-level battery manufacturers.

-

Ultra-high energy density

-

Ultra-high cycle stability

-

High safety

-

10000 x

-

9.00-10.50

D50( μm)

-

0.35-0.65

BET(m2/g)

-

47.90-49.50

Ni (wt%)

-

6.60-7.40

Co (wt%)

-

2.95-3.58

Mn(wt%)

-

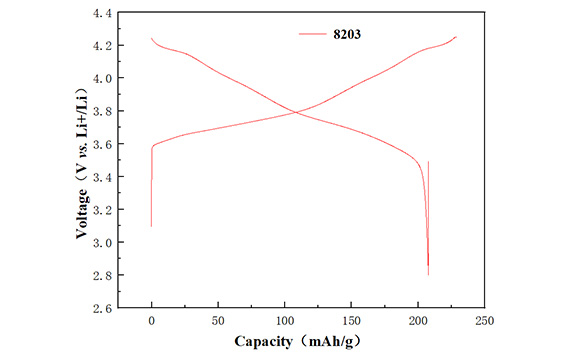

206.0-211.0

Initial specific discharge capacity (mAh/g) (2.8-4.25 V, at 0.1 C)

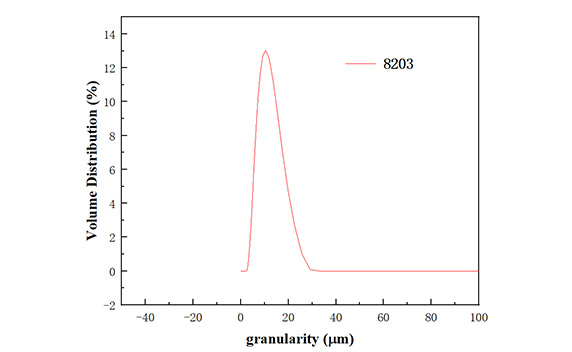

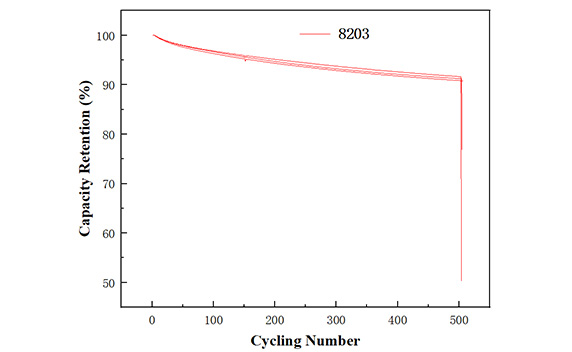

Technical Charts

-

-

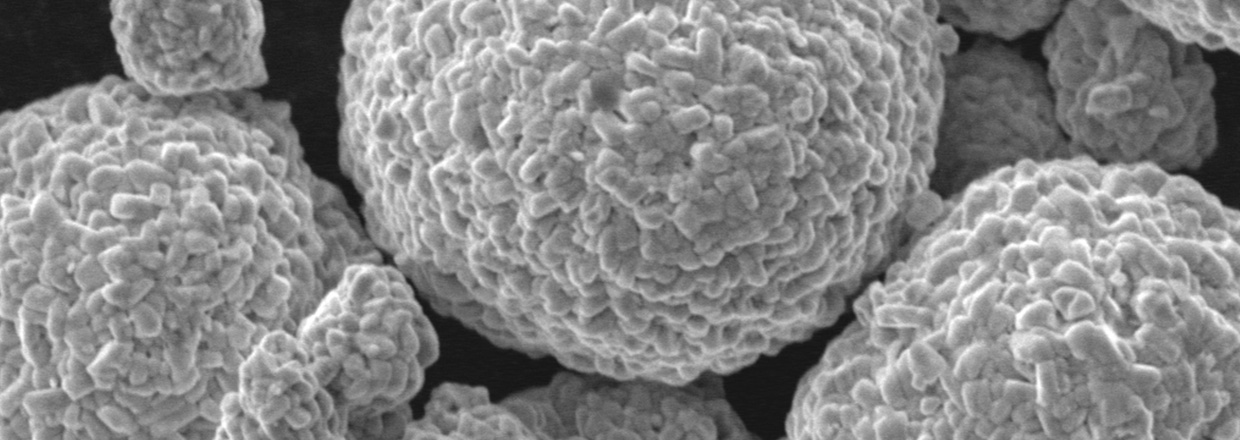

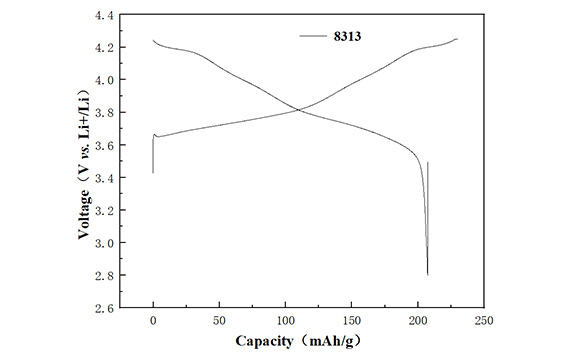

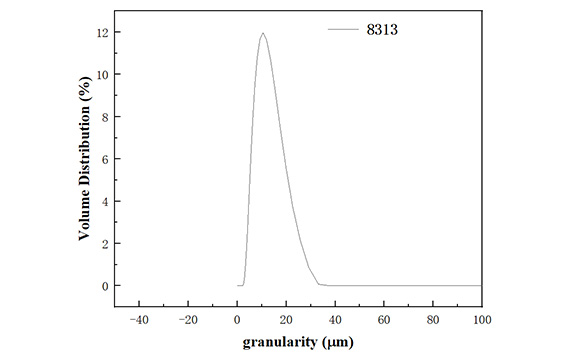

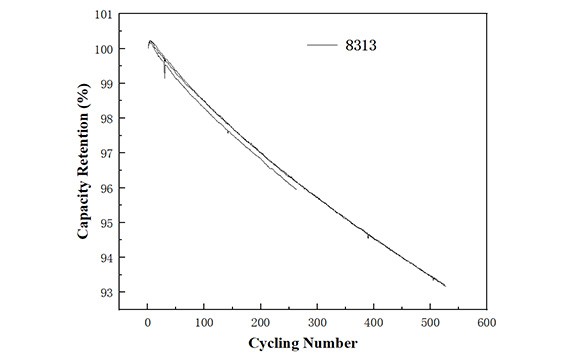

LL8313

LL8313 is a ternary cathode active material with extremely high cost-effectiveness. By precisely controlling and reducing cobalt content in the material, production cost of the material is significantly reduced, which continuously enpowers customers in cost control. LL8313 is a cathode active material with ultra-high energy density, compaction density and cycle stability, whose safety meets standards. Currently, it is mainly applied in transportation traction field including new energy vehicles with long endurance mileage.

-

Extremely high cost-effectiveness

-

Ultra-high energy density

-

Ultra-high compaction density

-

Ultra-high cycle stability

-

10000 x

-

9.05-11.70

D50( μm)

-

0.37-0.67

BET(m2/g)

-

48.1-50.50

Ni (wt%)

-

3.15-3.95

Co (wt%)

-

5.40-6.30

Mn(wt%)

-

205.3-209.8

Initial specific discharge capacity (mAh/g) (2.8-4.25 V, at 0.1 C)

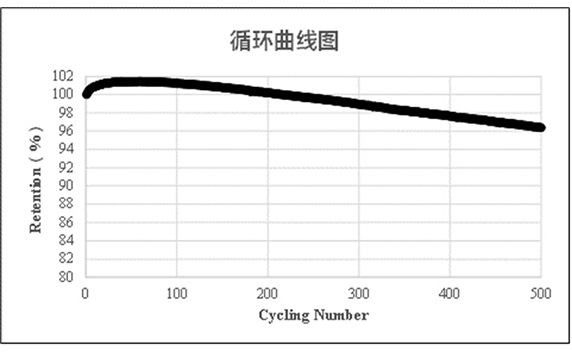

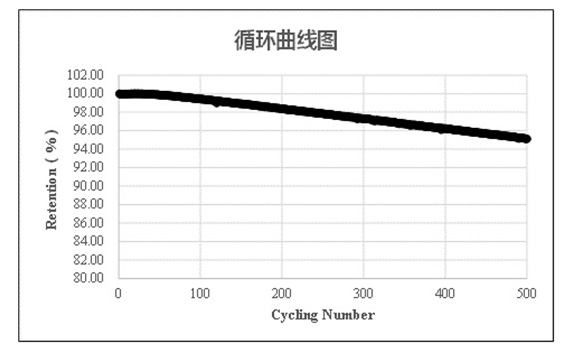

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

Cycling graph

-

-

LL9203

LL9203 is an ultra-high-nickel polycrystal ternary cathode active material product. Through the development for years, it has ultra-high energy density, and can circulate more than 1200 weeks at high temperature. On the basis of the 8-series material, without a water-washing process, residue alkali on a surface is precisely controlled and stable interface is simultaneously formed in the present product by means of coating and tempering, realizing high capacity, while ensuring cycle performance, storage performance and aerogenesis performance. Moreover, by optimization of particle size distribution on the basis of the 8-series materia, the compaction density of the material is further improved, and the mass energy density and volume energy density of the product are both improved obviously. Currently, it is mainly used in high-level or long-endurance new energy vehicle models.

-

Ultra-high energy density

-

Circulating more than 1200 weeks at high temperature

-

10000 x

-

9.0-11.0

D50(μm)

-

0.20-0.40

BET(m2/g)

-

53.0-54.3

Ni(wt%)

-

3.85-4.65

Co(wt%)

-

0.55-1.10

Mn(wt%)

-

≥227.0

Initial specific discharge capacity (mAh/g) (2.8-4.3 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

Cycling graph

-

-

LL9403

LL9403 is an ultra-high-nickel polycrystal ternary cathode active material. The structural stability of the material is optimized by strong pinning effect generated by high-entropy doping, the interfacial stability of the material is optimized by the in-situ synthesis of high-ionic conductivity electrolyte on the surface, and the residual lithium on the surface is removed by low-damage water washing, so as to further ensure the safety and interface stability of the cell under the premise that the material structure is not damaged. Brunp Recycling innovates a production process, so that the mass energy density and the volume energy density as well as aerogenesis performance of LL9403 exhibits outstandingly, while cycle and storage properties can continue to be excellent. Currently, the present product is mainly used in high-level or long-endurance new energy vehicle models.

-

Excellent energy density

-

Outstanding aerogenesis performance

-

Excellent storage performance

-

Excellent cycle performance

-

10000 x

-

≥3.6

D50(μm)

-

0.40-0.65

BET(m2/g)

-

54.2-55.8

Ni(wt%)

-

3.0-3.5

Co(wt%)

-

0.4-0.8

Mn(wt%)

-

≥228.3

Initial specific discharge capacity (mAh/g) (2.8-4.3 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

Cycling graph

-

-

HC4801

-

HC5001

-

HC4801

HC4801 is a lithium cobalt oxide cathode active material product independently developed by Brunp Recycling, has typical features of high capacity and high compaction density, and obvious advantages of high energy density and high voltage, and is now widely applied in the field of 3C.

-

High capacity

-

High compaction density

-

High energy density

-

High voltage

-

1000 x

-

15.2~16.2

Dv50(μm)

-

0.17~0.22

BET(cm2/g)

-

58.5~59.5

Co(wt%)

-

≥200

Specific charge capacity (mAh/g) (4.53 V, at 0.1 C)

-

≥188.5

Specific discharge capacity (mAh/g) (4.53 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

-

HC5001

HC5001 is a high-voltage lithium cobalt oxide cathode active material product independently developed by Brunp Recycling, has typical features of high capacity and high compaction density, and obvious advantages of high energy density and high voltage etc., and can satisfy high energy density requirement, which is widely applied in the field of 3C.

-

High capacity

-

High compaction density

-

High energy density

-

High voltage

-

1000 x

-

15.5~16.5

Dv50(μm)

-

0.17~0.22

BET(cm2/g)

-

58.5~59.5

Co(wt%)

-

≥204

Specific charge capacity (mAh/g) (4.55 V, at 0.1 C)

-

≥194.0

Specific discharge capacity (mAh/g) (4.55 V, at 0.1 C)

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

-

LL3503

-

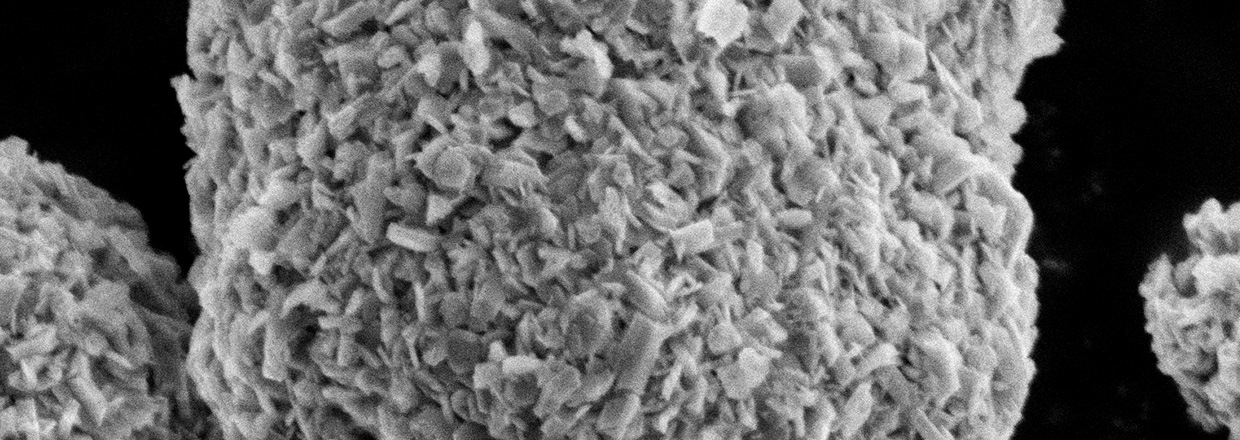

LL3503

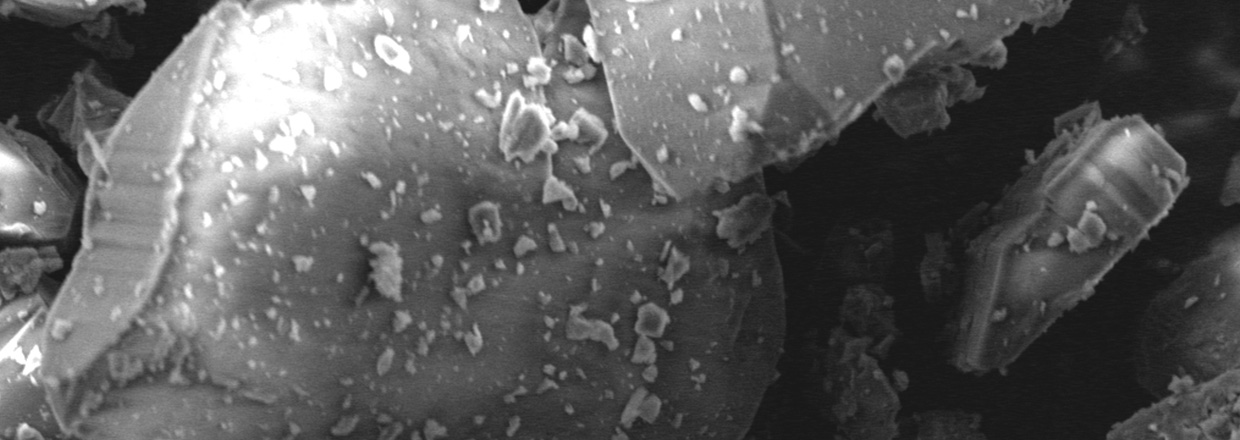

LL3503 is a lithium-rich cathode active material product with high-manganese and low-nickel. It is independently developed from the side of precursor by Brunp Recycling, the product has typical features of high capacity and high compaction density, as well as multi-dimension advantages including high energy density, high voltage, and high cost-effectiveness, and can simultaneously match requirements of high endurance mileage and low cost, is kind of product with great potential in the field of cathode active material.

-

High energy density

-

High voltage

-

High cost-effectiveness

-

10000 x

-

6~8

Dv50(μm)

-

<2

BET(m2/g)

-

58.5~59.5

Co(wt)%

-

≥230

Specific charge capacity (at 0.1 C) (mAh/g)

-

≥225

Specific discharge capacity (0.33C) (mAh/g)

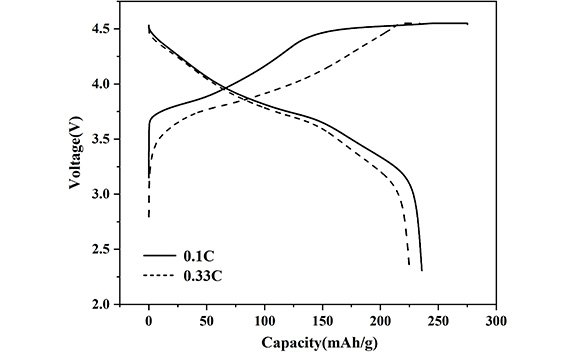

Technical Charts

-

Graph of curve of charge and discharge

-

Graph of particle size

-

Anode Material

-

Anode of Sodium Battery

-

Silicon and Carbon Anode

-

SA0101

-

SA0101

SA0101 is currently one of the few hard carbon products in a market, which can simultaneously realize high capacity and high initial coulombic efficiency. In Brunp Recycling, the structure of pores and channels of the product is precisely regulated, realizing high sodium storage capacity, and the product has also many advantages including high initial coulombic efficiency and low cost simultaneously, and can satisfy multiple requirements of customers on sodium-ion battery anode material in aspects of cost and performance.

-

High capacity

-

High initial coulombic efficiency

-

Low cost

-

2500 x

-

4~6

Dv50(μm)

-

<5

BET(m2/g)

-

>0.6

TD(g/cm3)

-

0.37-0.42

Interlayer spacing (nm)

-

≥320

Specific charge capacity (mAh/g)

Technical Charts

-

Graph of electrochemical performance

-

Graph of information on particle size

-

-

SN0104

-

SN0104

Through a development period of three years, SN0104 was applied in low-silicon traction battery item earliest. During the application, adding a small amount of the present product in a graphite can improve a capacity of the product, and the capacity retention rate reaches 80% or more after 2000 cycles.

-

Excellent cycle performance

-

20000 x

-

5000 x

-

1000 x

-

3.7~7.7

Dv50

-

0.70~1.70

BET

-

>0.0500

Mn(wt%)

-

>0.0300

Fe(wt%)

-

>0.0300

Cu(wt%)

-

>0.0300

Cr(wt%)

-

54.00~63.70

Si(wt%)

-

>56.0

Initial coulombic efficiency (wt%)

-

1350.0~1625.0

Initial coulombic efficiency (wt%)

-

0.5 ~1.5

C(wt%)

Technical Charts

-

Graph of electrical performance

-

Graph of particle size of silicon and carbon anode

-

Precursor

-

Ferric Phosphate

-

Hydroxide of Nickel, Cobalt and Manganese

-

FP0001

-

FP0002

-

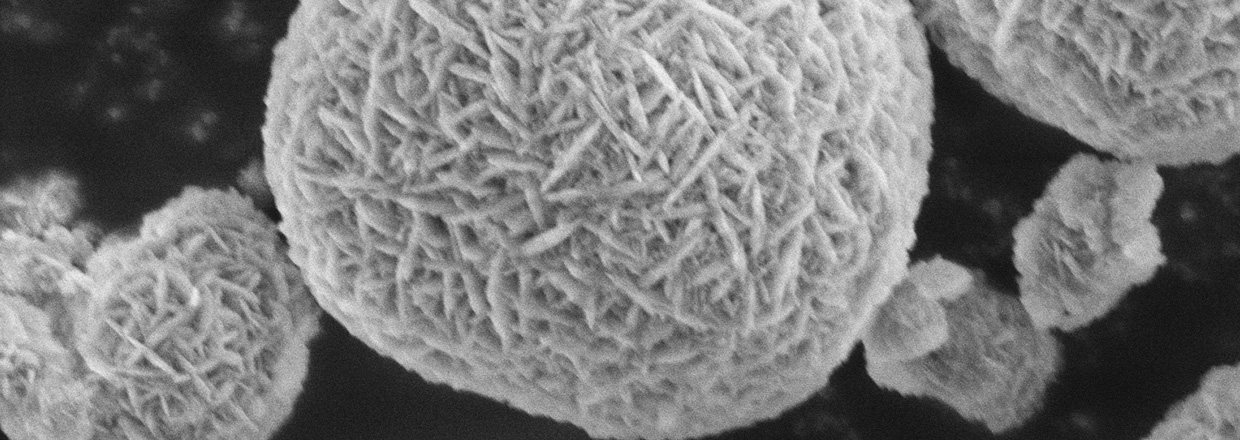

FP0001

FP0001 is a precursor product for lithium iron phosphate cathode active material. On the basis of alkali precipitation, Brunp Recycling makes a breakthrough on improvement of raw materials and process of the product, which obtain typical characters of high specific surface area and low sulphur. This product, with high specific surface area, low impurity content, and high tap density, can satisfy a requirement of lithium iron phosphate with high compaction, and can attain performance requirement for 3rd-generation compaction and be close to performance requirement for 4th-generation compaction. FP0001 has been widely applied in fields of traction transportation, electric tool, energy storage, and communication etc., is an important raw material for preparing lithium iron phosphate cathode active material, and is occupying the mainstream market in the field of cathode active material.

-

High specific surface area

-

Low impurity

-

High tap density

-

50000 ×

-

5000 ×

-

7.6±1

BET(m2/g)

-

36.60±0.15

Fe content ( %)

-

20.80±0.15

P content (%)

-

≤500

S content (ppm)

-

0.975±0.005

Fe/P(molar ratio)

Technical Charts

-

Graph of distribution of particle size

-

-

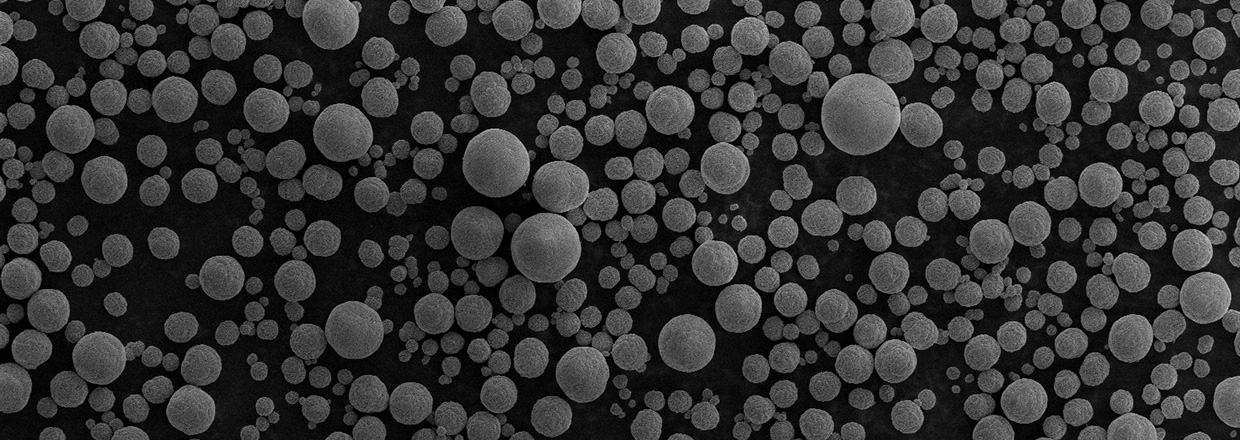

FP0002

FP0002 is a precursor product for lithium iron phosphate cathode active material. Brunp Recycling prepares battery-grade ferric phosphate by using slag of phosphorus and iron of waste lithium iron phosphate powder after lithium extraction as raw material. The present product has advantages of simple process, high tap density, and low cost etc., can satisfy requirement for lithium iron phosphate with high compaction, and attains performance requirement for compaction of 2nd-generation and 3rd-generation. Currently, this product is applied in fields of traction transportation, electric tool, energy storage, and communication etc., is an important raw material for preparing lithium iron phosphate cathode active material, and is occupying the mainstream market in the field of cathode active material.

-

Simple process

-

High tap density

-

Low cost

-

1000 ×

-

2-6

BET(m2/g)

-

36.60±0.15

Fe content (%)

-

20.80±0.15

P content (%)

-

≤500

S content (ppm)

-

0.975±0.005

Fe/P(molar ratio)

-

-

PH5003

-

PH5007

-

PH5503

-

PH6506

-

PH8302

-

PH8303

-

PH9203

-

PH9401

-

PH5003

PH5003 is a medium-nickel precursor product for ternary cathode, with a nickel content being 50%. Currently, it is mainly applied in the field of polycrystal cathode active material for digital or small-power products. A molar ratio of main contents can be directionally designed.

-

Directional design

-

10000 x

-

1000 x

-

10.0±1.0

D50(μm)

-

6.0±2.0

BET(m2/g)

-

50.0±0.5

Ni(mol%)

-

20.0±0.5

Co(mol%)

-

30.0±0.5

Mn(mol%)

Technical Charts

-

-

PH5007

PH5007 is a precursor product of medium-nickel, small-particle for ternary cathode with nickel content of 50%. Currently, it is mainly applied in the field of monocrystal cathode active material for digital or power products. A molar ratio of main contents can be directionally designed.

-

Directional design

-

50000 x

-

10000 x

-

1000 x

-

3.9±0.5

D50(μm)

-

9.0±3.0

BET(m2/g)

-

50.0±0.5

Ni(mol%)

-

20.0±0.5

Co(mol%)

-

30.0±0.5

Mn(mol%)

Technical Charts

-

Graph of distribution of particle size

-

-

PH5503

PH5503 is a medium-nickel, small-particle precursor for ternary cathode with nickel content of 55%. Currently, it is mainly applied in the field of power monocrystal cathode active material. A molar ratio of main contents can be directionally designed.

-

Directional design

-

50000 x

-

10000 x

-

3.9±0.5

D50(μm)

-

9.0±3.0

BET(m2/g)

-

55.0±0.5

Ni(mol%)

-

12.0±0.5

Co(mol%)

-

33.0±0.5

Mn(mol%)

Technical Charts

-

Graph of distribution of particle size

-

-

PH6506

PH6506 is a medium-nickel, small-particle precursor for ternary cathode with nickel content of 65%. Currently, it is mainly applied in the field of monocrystal cathode active material for traction. A molar ratio of main contents can be directionally designed.

-

Directional design

-

50000 x

-

10000 x

-

1000 x

-

3.8±0.4

D50(μm)

-

9.0±2.0

BET(m2/g)

-

65.0±0.5

Ni(mol%)

-

7.0±0.5

Co(mol%)

-

28.0±0.5

Mn(mol%)

Technical Charts

-

Graph of distribution of particle size

-

-

PH8302

PH8302 is a high-nickel precursor product for ternary cathode with nickel content of 83%, and cobalt content of 12%. It has advantages of long cycle life, high energy density, high safety and low cost etc., and can satisfy requirements for high endurance mileage, high safety and low cost. A molar ratio of main contents can be directionally designed.

-

Long cycle life

-

High energy density

-

High safety

-

Low cost

-

Directional design

-

50000 x

-

10000 x

-

1000 x

-

10.0±1.0

D50(μm)

-

7.0±2.0

BET(m2/g)

-

83.0±0.5

Ni(mol%)

-

12.0±0.5

Co(mol%)

-

5.0±0.5

Mn(mol%)

Technical Charts

-

-

PH8303

PH8303 is a precursor product of high-nickel for ternary cathode with nickel content of 83%, and cobalt content of 12%. It has advantages of long cycle life, high energy density, high safety and low cost etc., and can satisfy requirements for high endurance mileage, high safety and low cost. A molar ratio of main contents can be directionally designed.

-

Long cycle life

-

High energy density

-

High safety

-

Low cost

-

Directional design

-

50000 x

-

10000 x

-

1000 x

-

3.8±0.4

D50(μm)

-

15.0±2.0

BET(m2/g)

-

83.0±0.5

Ni(mol%)

-

12.0±0.5

Co(mol%)

-

5.0±0.5

Mn(mol%)

Technical Charts

-

Graph of distribution of particle size

-

-

PH9203

PH9203 is a precursor product of ultra-high-nickel for ternary cathode, with nickel content being 92%. It has advantages of long cycle life, high energy density, high safety and environmental friendliness etc., and can satisfy requirement for high endurance mileage. The product has great potential in the field of material, has been applied in the field of high-level electric vehicle, is an important raw material for preparing electric vehicle battery with long endurance mileage. A molar ratio of main contents can be directionally designed.

-

Long cycle life

-

High energy density

-

High safety

-

Environmental friendliness

-

Directional design

-

50000 x

-

10000 x

-

5000 x

-

1000 x

-

10.0±1.0

D50(μm)

-

8.0±2.0

BET(m2/g)

-

92.0±0.5

Ni(mol%)

-

5.0±0.5

Co(mol%)

-

3.0±0.5

Mn(mol%)

Technical Charts

-

-

PH9401

PH9401 is a ultra-high-nickel, small-particle precursor product for ternary cathode with nickel content of 94%. It's currently mainly applied in the field of monocrystal cathode active material for traction, A molar ratio of main contents can be directionally designed.

-

Directional design

-

50000 x

-

10000 x

-

1000 x

-

3.6±0.4

D50(μm)

-

16.0±2.0

BET(m2/g)

-

94.0±0.5

Ni(mol%)

-

4.0±0.5

Co(mol%)

-

2.0±0.5

Mn(mol)

Technical Charts

-

Graph of distribution of particle size

-

Minerals

-

Ferronickel

-

FeNi20

-

FeNi20

FeNi20 is a direct product of RKEF smelting process. Based on RKEF smelting process, Brunp Recycling makes creative development breakthrough along directions of refining and impurity removal of ferronickel, and powdering of ferronickel etc., continuously improving leaching rates of ferronickel powder. The present product has advantages of high cost-effectiveness, high safety, wide application range, superior quality, great scale, low cost and environmental friendliness etc. in aspects of preparation of lithium iron phosphate and ternary material. Currently, this product has been widely applied in fields of stainless steel, special steel and heat-resistant steel castings, the prepared nickel and iron powder can be used in fields of magnetic material, catalyst, and electroplating etc., is an important raw material for preparing lithium iron phosphate and ternary precursor, and occupies a mainstream market in the field of preparing ferric phosphate, lithium iron phosphate and ternary material.

-

High cost-effectiveness

-

High safety

-

Wide application range

-

Superior quality

-

Low cost

-

Environmental friendliness

-

Product

-

10000 ×

-

5000 ×

-

1000 ×

-

1430~1480

Melting point (℃)

-

8.1~8.4

Density (g/cm3)

-

10~30

Ni(%)

-

1~3.6

C(%)

-

<0.2

Si(%)

-

<0.03

P(%)

-

0.2~0.5

S(%)

-

Lithium Salt

-

Lithium Carbonate

-

Lithium Hydroxide

-

LC0101

-

LC0101

LC0101 is a lithium salt product transformed from recycled batteries. The development in battery recycling goes through several years, resulting in product with low impurity content and wide application, which takes great market superiority. The product is widely applied in fields of smartphone, notebook computer, and electric vehicle etc., and is important raw materials for preparing lithium-ion battery.

-

Low impurity content

-

Wide application range

-

10000 x

-

5000 x

-

2500 x

-

≤0.25

Water (%)

-

≤0.50

Loss on ignition (%)

-

≤200

Magnetic impurity (ppb)

-

≥90.0

Whiteness

-

4.1-6.6

D50(μm)

-

<0.03

P(%)

-

≥99.55

Main content of lithium carbonate (%)

-

-

LH0102

-

LH0102

Lithium hydroxide monohydrate is another important lithium product transformed from recycled batteries, which is a main raw material for other lithium salts, and is an important raw material for preparing ternary cathode active material.

-

Wide application range

-

30000 x

-

10000 x

-

5000 ×

-

≤75

Magnetic impurity (ppb)

-

≤800

D50(um)

-

≥16.47-16.90

Li content (%)

-